Speaker

Description

Fe-based metallic glasses (MGs) exhibit superior soft magnetic properties such as a very low coercivity and power losses, a low magnetostriction and a high permeability [1]. Their magnetic properties can be further optimized by modification of post-processing conditions, such as temperature and duration of heat treatment. Structural characterization of MGs at the atomic level represents an ambitious task. The atomic arrangement in amorphous alloys is still not well understood compared with the well-defined long-range order in crystalline materials. Experimental methods like X-ray diffraction, transmission electron microscopy, small angle X-ray scattering, X-ray absorption spectroscopy and Mössbauer spectroscopy are usually applied for structural investigations of metallic glasses. However, all these experimental techniques suffer from limited brightness of the sources they use. This in turn implies rather low level of signal, which is inherent to highly disordered materials such as MGs. With the advent of 3rd generation synchrotron radiation sources and recent technological breakthroughs in photon detectors it is possible to acquire high-quality scattering data enabling quantitative study of local atomic structure of MGs. It has been recently demonstrated that the high energy X-ray scattering of synchrotron radiation can be used to track tiny structural changes in the structure of metallic glasses when exposed to thermal [2] or mechanical loading [3].

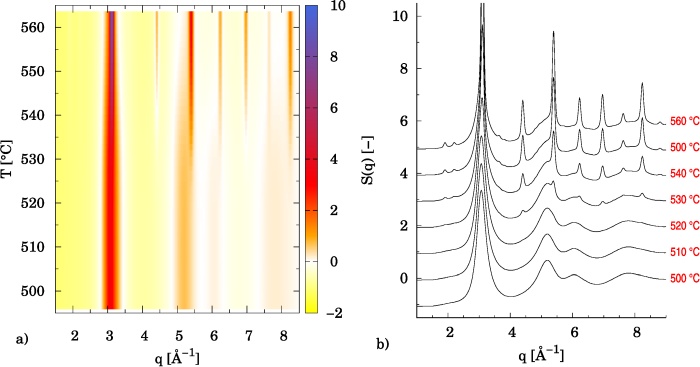

Fig. 1 a) Series of structure factors $S(q)$ of the Vitroperm alloy acquired during constant rate heating in-situ experiment. b) Comparison of selected $S(q)$ in the vicinity of crystallization. Sharp peaks correspond to the Bragg reflections of Fe$_{3}$Si cubic phase.

In this work we demonstrate the advantage of high-energy synchrotron radiation in studying changes in local atomic structure of Fe-base metallic glass (Vitroperm-800) induced by thermal loading. In the first part we present data obtained by thermally cycling the Vitroper-800 alloy in the temperature region well below its crystallization temperature $T_{x}$. Obtained data suggest irreversible structural changes which are fingerprint of amorphous structure relaxation. When performing constant rate (10 $^\circ$C/min) heating in-situ experiment from 20 up to 560 $^\circ$C, initially amorphous alloy undergoes crystallization at around $T_{x}$ = 515(5) $^\circ$C, which is in perfect agreement with earlier results. Above crystallization temperature the Bragg peaks stemming from Fe$_{3}$Si cubic phase are clearly visible (see Fig.1). To quantitatively characterize the mean grain size of Fe$_{3}$Si nanocrystals as a function of temperature (above $T_{x}$) analysis based on pair distribution function (PDF) was employed. It turns out that PDF approach is robust, and growth of ultra small grains can be reliably detected in the early stages of nanocrystal formation.

Acknowledgements

Vitroperm-800 alloy in the form of thin ribbon was kindly provided by Dr. G. Herzer from VACUUMSCHMELZE GmbH Hanau, Germany. This research was financially supported by a Slovak Scientific Grant Agency VEGA (project No. VEGA 1/0638/24).

References

[1] M. E. McHenry, M. A. Willard, and D. E. Laughlin, “Amorphous and nanocrystalline materials for applications as soft magnets,” Progress in Materials Science, vol. 44, no. 4. Elsevier BV, pp. 291–433, Oct. 1999. doi: 10.1016/s0079-6425(99)00002-x.

[2] H. F. Poulsen, J. A. Wert, J. Neuefeind, V. Honkimäki, and M. Daymond, “Measuring strain distributions in amorphous materials,” Nature Materials, vol. 4, no. 1. Springer Science and Business Media LLC, pp. 33–36, Dec. 19, 2004. doi: 10.1038/nmat1266.

[3] J. Bednarcik, S. Michalik, V. Kolesar, U. Rütt, and H. Franz, “In situ XRD studies of nanocrystallization of Fe-based metallic glass: a comparative study by reciprocal and direct space methods,” Physical Chemistry Chemical Physics, vol. 15, no. 22. Royal Society of Chemistry (RSC), p. 8470, 2013. doi: 10.1039/c3cp44445g.