The XIV European Magnetic Sensors and Actuators Conference

Lecture Hall

Košice, Slovakia

We are glad to announce that the XIV. European Magnetic Sensors and Actuators Conference (EMSA 2024) will take place in Kosice from 24th to 27th June of 2024 at the University of Pavol Jozef Safarik in Kosice, Slovakia, located in the very center of Kosice city.

The European Magnetic Sensors and Actuators Conference (EMSA) is a consolidated European forum that serves to assess the status, recent progress, and development in the field of magnetic sensor technology and magnetic actuators. It was first held in 1996 in Iasi (Romania) and since then has continued every two-three years in different European cities. The aim of the conference is to generate an overview of research in magnetic sensors and actuators, to recognize their relevance in modern industry and to identify potential future collaborations. EMSA 2024 will provide an excellent opportunity to bring together scientists and engineers from universities, research institutes and industry to present and discuss their most recent results covering both fundamental and applied aspects of magnetic sensors and actuators.

Conference topics:

- Novel magnetic materials

- Modelling and simulation

- Magnetic sensors

- Magnetic actuators

- Magnetic MEMS

- Biomedical Applications of sensors and actuators

- Applications of spin phenomena

- Other applications

- Metrology

We hope this Conference will reach the high scientific level and the careful organization of the previous EMSAs.

We are looking forward to your scientific contribution.

See you in June 2024!!!

prof. R. Varga

(on behalf of organizing committee)

-

-

16:00

→

18:00

Registration 2h Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1 -

18:00

→

21:00

WELCOME party 3h MINERVA

MINERVA

Doktora Kostlivého 576/1

-

16:00

→

18:00

-

-

08:00

→

09:00

Registration 1h Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1 -

09:00

→

09:10

Opening ceremony 10m Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1 -

09:10

→

09:30

EMSA History & Future 20m Lecture Hall (Košice)

Lecture Hall

Košice

Doktora Kostlivého 576/1Speaker: Evangelos Hristoforou (Sensors Lab, National Technical University of Athens) -

09:30

→

10:30

TUE: Session 1 Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1Convener: Pavel Ripka (CVUT FEL (Czech Technical University, Faculty of Electrical Engineering))-

09:30

Low Noise Magnetoelectric Composite Sensors 30m

Magnetic field sensors are devices that detect and measure magnetic fields around permanent magnets, electrical conductors, and electrical devices. As such, they are particularly relevant for applications in IoT, 5G, smartphones, energy, and biomedical engineering. In this context, dedicated research is being carried out on novel thin film composite magnetoelectric (ME) sensor concepts for the detection of magnetic fields down to the picotesla range. Advanced wide-field magneto-optical Kerr effect microscopy with high temporal resolution is used to study local effects in operating ME composite sensor structures. Together with supporting electrical measurements, the realized magnetospatial analysis of working devices sheds light on magnetization changes due to domain nucleation, domain wall resonances, domain wall bending modes, and spin-wave-like phenomena. Each of these is specific to different types of composite ME sensors, ranging from resonance to modulated to $\Delta E$ to SAW sensor systems. Complementary electrical noise and detection limit analyses reveal the different noise mechanisms, electrical and magnetic, for the different sensors. By understanding the complex magnetic interactions, strategies and implementations are identified to optimize magnetic sensor structures.

The design and application of flux closing magnetic multilayer structures with minimal noise is discussed. Magnetostatically stabilized but still responsive single magnetic domain layers are the basis for low noise sensors due to the absence of magnetic domain walls. Limits for sensitivity enhancement from additional magnetoelastic domain effects will be discussed. Beyond magnetic domain engineering, other schemes of magnetic noise suppression, based on a combination of sensing and pinning magnetic multilayer stacks are demonstrated. By introducing special magnetic sensing layers the influence of the electrical carrier signal to noise is virtually eliminated. The magnetically enforced reduction of the electrical background signal paves the way for ultra-low noise ME sensor applications capable of detecting picotesla magnetic fields. We show that with the current approaches and beyond magnetic domain activity, we are seeing novel effects based on non-linear magnetoelastic effects. Low noise sensor detectabilities are now approaching fundamental limits.

Acknowledgements

Funding by the DFG for the CRC 1261 “Magnetoelectric Sensors: From Composite Materials to Biomagnetic Diagnostics” is highly acknowledged.

References

[1] L. Thormählen et al., “Low-noise inverse magnetoelectric magnetic field sensor,” Applied Physics Letters, vol. 124, no. 17. AIP Publishing, Apr. 22, 2024. doi: 10.1063/5.0196637.

[2] E. Spetzler, B. Spetzler, and J. McCord, “A Magnetoelastic Twist on Magnetic Noise: The Connection with Intrinsic Nonlinearities,” Advanced Functional Materials, vol. 34, no. 9. Wiley, Nov. 20, 2023. doi: 10.1002/adfm.202309867.

[3] V. Schell et al., “Exchange biased surface acoustic wave magnetic field sensors,” Scientific Reports, vol. 13, no. 1. Springer Science and Business Media LLC, May 25, 2023. doi: 10.1038/s41598-023-35525-6.

[4] C. Müller et al., “Imaging of Love Waves and Their Interaction with Magnetic Domain Walls in Magnetoelectric Magnetic Field Sensors,” Advanced Electronic Materials, vol. 8, no. 6. Wiley, May 04, 2022. doi: 10.1002/aelm.202200033.

[5] P. Durdaut et al., “Phase Noise of SAW Delay Line Magnetic Field Sensors,” Sensors, vol. 21, no. 16. MDPI AG, p. 5631, Aug. 21, 2021. doi: 10.3390/s21165631.Speaker: Jeffrey McCord (Kiel University) -

10:00

Limitation in Ni2FeGa Microwires Design as Sensor/Actuator with Focus on Shape Memory Effect 15m

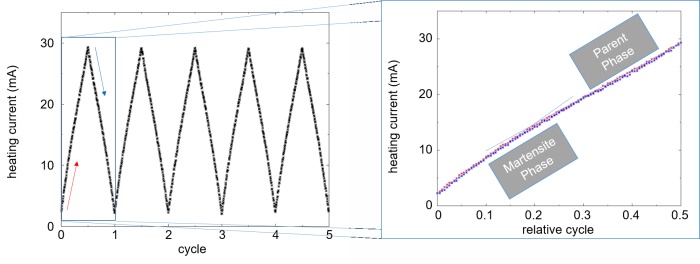

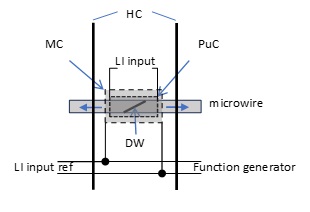

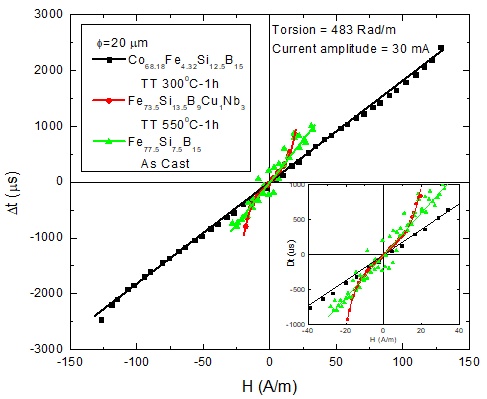

The microwires due to their dimensions have a huge potential in wide fields from agricultural, medical, and technological high-end applications such as sensors or actuators. On the one hand, designing different types of materials for each application is possible. On the other hand, there is the scalability of dimensions, which brings opportunities to control the physical properties of the microwire material [1].

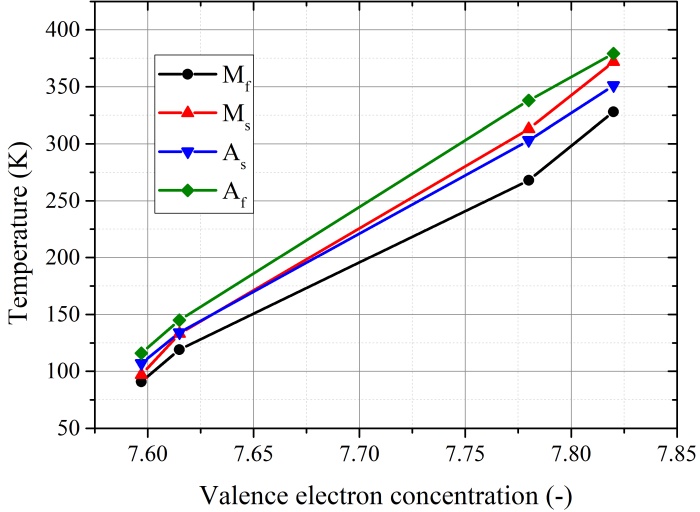

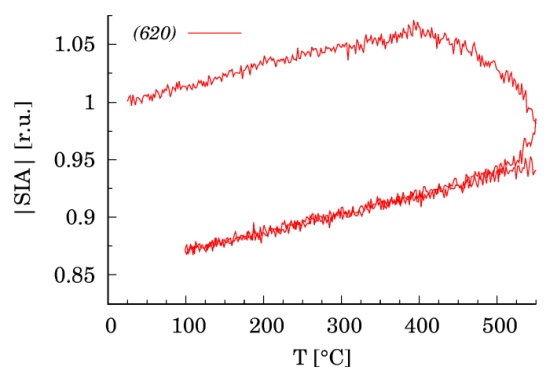

One of the interesting candidates among microwires is the Heusler alloy, specifically Ni$_2$FeGa. In this alloy takes place the phase transformation from a high-temperature ordered phase to a low-temperature phase. Since the transformation is thermos-elastic, the alloy exhibits a shape memory phenomenon. It is already known that the temperature range of phase transformation could be changed from 50 K up to 400 K by fine-tuning the alloy chemical composition [2]. Setting the transformation temperature, which affects material's sensitivity to the change in its magnetic properties, is very important for its applicability. This work will present the influence of chemical composition tuning on the microstructure, phase transformation temperature (see Fig. 1), physical properties, and limitations of the shape memory effect.

Fig. 1 The transformation temperature in dependence on valence electron concentration.

Acknowledgements

This work was supported by Slovak VEGA 2/0086/22 and VEGA 1/0180/23.

References

[1] R. Jurc et al, “Sensoric application of glass-coated magnetic microwires“, (2020) Magnetic Nano- and Microwires: Design, Synthesis, Properties and Applications, 2020, pp. 833-868. doi: 10.1016/B978-0-08-102832-2.00028-1.

[2] M. Hennel, L. Galdun, R. Varga, “Analysis of magnetocaloric effect in Ni2FeGa-based glass-coated microwires”, Materials, vol. 560, art. no. 169646, Oct. 2022. doi: 10.1016/j.jmmm.2022.169646.Speaker: Ondrej Milkovic (Institute of Materials Research, Slovak Academy of Sciences) -

10:15

Mobile Robots based on Multipole Magnetoactive Elastomer for Controllable Planar Locomotion 15m

Magnetoactive elastomers (MAEs) consist of an elastic matrix with embedded micron-sized soft and/or hard magnetic particles. Such elastomers change their mechanical and rheological properties under the influence of external or internal magnetic fields. The magnetization of MAEs with hard magnetic particles in a strong magnetic field enables to produce elastic permanent magnets.

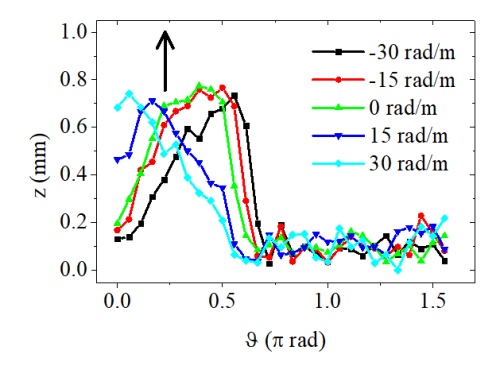

Magnetized MAEs are promising for use in the field of soft robotics. Motion systems realized using MAEs can achieve movement with a minimum number of actuators. In this work, the locomotion systems are made of a special type of MAEs as a functional element. We use beam-shaped MAEs, which are synthesized from a mixture of hard and soft magnetic particles. The MAE beams are permanently magnetized in a way that there is a south pole in the middle and a north pole at each end. The motion principle of the locomotion systems is based on the magnetic-field-induced bending deformation of the magnetized beam. The alternating magnetic field causing the beam deformation is generated by an electromagnetic coil integrated into the robot’s casing. Silicone bristles on the underside of the MAE beam provide asymmetrical friction conditions. Due to the cyclic interplay of friction forces and inertial forces caused by periodic bending, the robot shifts its position in each cycle and thereby moves forward. The movement speed is strongly dependent on the actuating frequency, with a maximum speed being achieved in the resonance range [1]. The use of two MAE functional elements, that are positioned parallel and mirror-symmetrical to each other, enables movement in a plane (Fig. 1). The principle of skid-steer is utilised. The movement speed along a curved path is determined by the choice of two actuating frequencies of the coils. The developed locomotion systems demonstrate good maneuverability and controllability. Their actuation method makes it easy to change the translational speed and yaw angle, making such systems suitable for use in complex operating conditions.

Fig. 1 Locomotion system for planar movement, left: top view, right: side view.

Acknowledgements

The work is funded by the Deutsche Forschungsgemeinschaft (DFG), project BE-6553/2-1.

References

[1] M. Reiche, T. I. Becker, G. V. Stepanov, and K. Zimmermann, “A Multipole Magnetoactive Elastomer for Vibration-Driven Locomotion,” Soft Robotics, vol. 10, no. 4. Mary Ann Liebert Inc, pp. 770–784, Aug. 01, 2023. doi: 10.1089/soro.2022.0106.

Speaker: Marius Reiche

-

09:30

-

10:30

→

11:00

Coffee break 30m MINERVA

MINERVA

Doktora Kostlivého 576/1 -

11:00

→

12:30

TUE: Session 2 Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1Convener: Marco Coïsson (INRIM)-

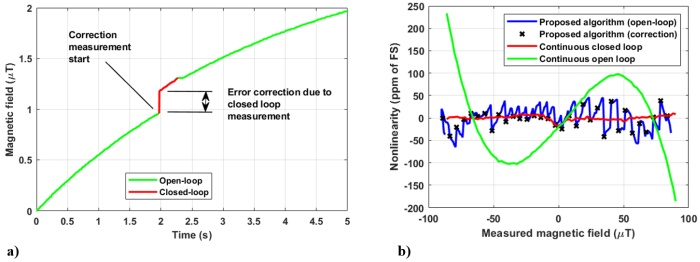

11:00

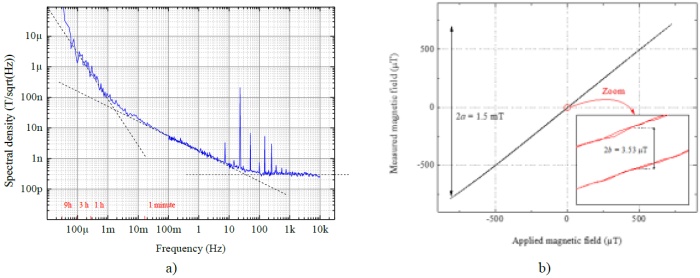

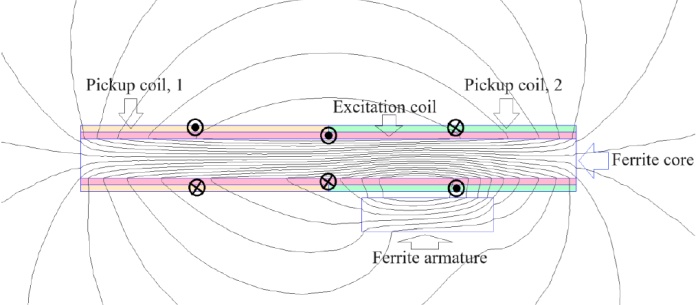

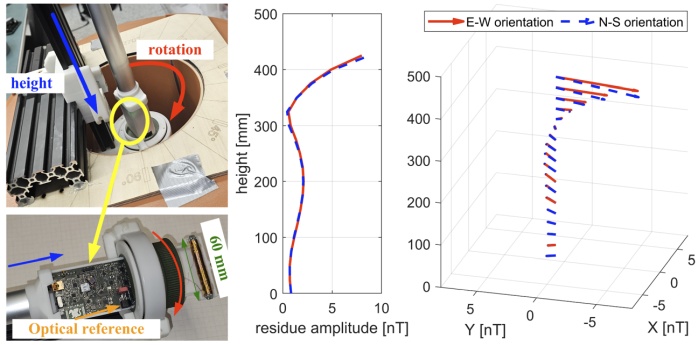

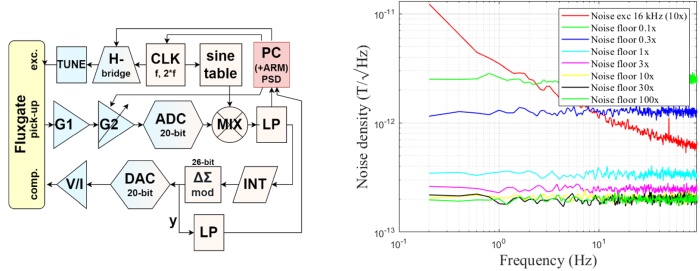

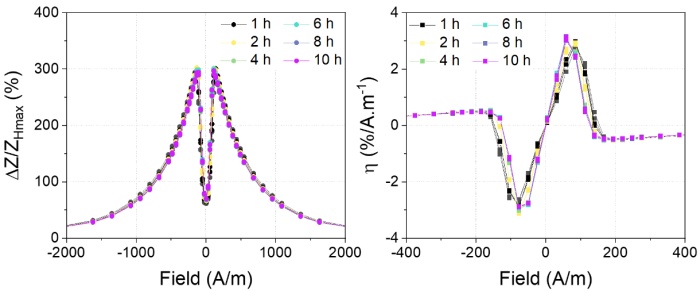

Low Noise Fluxgate Sensors for Biomedical Applications 30m

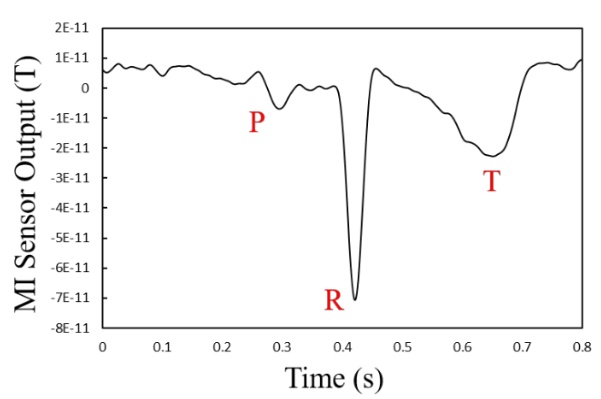

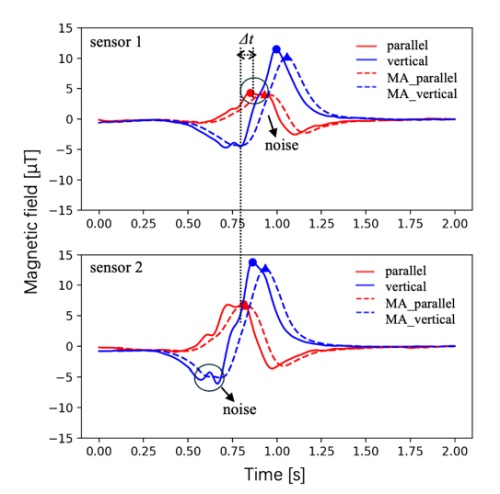

Biomedical applications typically require very low noise magnetic sensors, since the magnetic field to be measured are usually very small. Traditionally SQUIDs have been the only sensors able to reach noise levels low enough to be employed in this field. However, the necessity of cryogenic temperature limits the applications of these sensors to fields where extremely low noise is required. Meanwhile, during the last lustra the noise of other sensors have been strongly reduced until becoming competitive in fields like magnetocardiography where tens of pT in a bandwidth from 1 Hz to few tens of Hz is required. Among them orthogonal fluxgate have shown remarkable results achieving noise well below 1 $\mathrm{pT}/\sqrt{Hz}$ in the bandwidth of interest [1]. One of the advantages of orthogonal fluxgates is the high spatial resolution which, together with the low cost allowed to create a matrix of sensors to map the magnetic field produced by a human heart [2].

In this contribution I will present how it was possible to achieve these results. Starting from the requirements for magnetocardiography (MCG) diagnostic and in particular the necessity to measure the T wave on a large number of points, I will present the methods used to achieve low noise magnetometer with high spatial for MCG. These include the development of a composition for amorphous Co-rich magnetic microwires which retain low magnetostriction when annealed to increase their circular anisotropy; this is obtained by decreasing the amount of iron so that the negative magnetostriction becomes close to zero after annealing. I will present the dependence of the noise on the geometry of the sensor and in particular how to increase the spatial resolution in the axis of the sensor without causing an excessive increase of noise. Unexpectedly, even using multiple shorter coils on the same core does not significantly increase the noise.

A very important aspect of biomagnetic fields is that they rapidly decay in space, therefore one my be lead to believe that, for instance, just a few cm far from the chest the MCG signal is vanishing and not measurable. From this point of view we show how the ferromagnetic core of the fluxgate acts as a flux concentrator which carries the signal even at several centimeters far from the chest making it measurable. An important focus will be given to the electronic which creates low noise excitation current for the sensors, as well as amplify and demodulate the signal from the pick-up coil and how this was designed to minimized the noise of the magnetometer. In particular, I show how a proper design of the preamplifier can reduce the current absorbed by the coil and return higher sensitivity contributing to decrease the noise floor of the sensor.

Another important aspect of the implementation of orthogonal fluxgates for real-life applications like MCG is the manufacturing process of the sensor itself. Traditionally fluxgates are known to have a low noise only on few samples over a large batch of produced sensors. Since applications like MCG require a large number of sensors with low cost it would not be feasible to use this technology unless a very high yield ratio. I will show how we managed to achieve a yield larger than 95 $\%$ on batch of serially produced sensor, proving that the technology is ready for mass implementation. Finally I will also discuss the limitations of this technology with special regard to offset stability with temperature and how, however, this limitations can be mitigated when not directly corrected.

Speaker: Mattia Butta Gonzales (Faculty of Electrical Engineering, Czech Technical University in Prague) -

11:30

Development of Planar Hall Magnetoresistive Sensor and its Application for Magnetic Encoder 15m

Performance of planar Hall magnetoresistive (PHMR) sensors was measured in different specification, such as sensor layer thickness, geometry [1]. We figured out the change in PHMR sensor performance for each factors and applied into magnetic encoder experiments. In this magnetic encoder experiments, PHMR sensor was located near to steel gear and permanent magnet was located behind the PHMR sensor to induce stray field from magnetized steel gear. Signal from PHMR sensor was compared in different factors, such as distance between gear-sensor, distance between sensor-magnet or direction of sensor and magnet, etc. Total harmonic distortion (THD), signal amplitude and phase difference were main performance requirements, but those are not satisfied in our traditional multi-ring type NiFe/IrMn bilayer sensors. New ferromagnetic material and sensor geometry were applied to encoder sensors to enhance the main performance requirements and the experimental result was discussed in this speech.

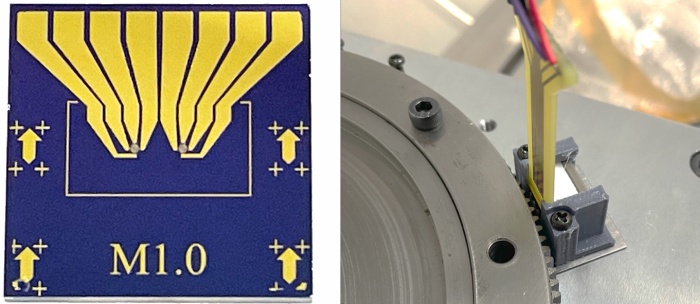

Fig. 1 Optical microscope image of PHMR sensor (left) and magnetic encoder using PHMR sensor (right).

Acknowledgements

This research was supported by a National Research Foundation (NRF) grant funded by the MSIT (Grant No. NRF-2018R1A5A1025511).

References

[1] T. Jeon et al., “Operational Parameters for Sub-Nano Tesla Field Resolution of PHMR Sensors in Harsh Environments,” Sensors, vol. 21, no. 20. MDPI AG, p. 6891, Oct. 18, 2021. doi: 10.3390/s21206891.

Speaker: Taehyeong Jeon (Daegu Gyeongbuk Institute of Science and Technology) -

11:45

Investigating Neutron Radiation Induced Damage on Novel Type of Hall-Effect Sensors 15m

Our research explores the potential use of semiconductor thin-film materials and graphene-based structures for magnetic field detection in harsh environments, particularly in thermonuclear reactors. We have conducted preliminary research to investigate the impact of high temperature [1] and neutron irradiation [2,3] on the electrical properties of these sensors. Our studies involved a 2D material made from hydrogen-intercalated quasi-free-standing graphene on semi-insulating 4H-SiC (0001), passivated with an Al$_2$O$_3$ layer [4], and a donor-doped InSb-based thin-film on a semi-insulating GaAs substrate [2]. Our research has shown how described systems were affected by fast neutron fluence of $7\times 10^{17}$ cm$^{-2}$ using MARIA research nuclear reactor. Based on Hall effect measurements and micro-Raman analysis, we conjecture that for graphene-based structure after irradiation, the primary factor impacting the electrical characteristics is the depletion of atoms in the hydrogen layer. This phenomenon is expected to decrease the surface area of intercalation which becomes too scarce to support graphene separation. However, we observe self-healing abilities at temperatures higher than 200 $^{\circ}$C [3]. To determine if these materials are suitable for magnetic field sensing in thermonuclear reactors, we need to understand how they will be affected by stronger neutron radiation. Therefore, we investigate new modes of damage in 5 times greater neutron fluence ($40\times 10^{17}$ cm$^{-2}$) and how the effects of neutron irradiation differ when the graphene-based sensor’s substrate polytype is changed to 6H-SiC (0001).

Acknowledgements

The research has received funding from the National Centre for Research and Development under Grant Agreement No. LIDER/8/0021/L-11/19/NCBR/2020 for project MAGSET and partly from the Ministry of Education and Science (Poland) under Project No. 0512/SBAD/2420.

References

[1] W. Reddig, et al., “High-Temperature Stability of Sensor Platforms Designed to Detect Magnetic Fields in a Harmful Radiation Environment,” IEEE Sensors Letters, vol. 7, no. 8, Aug. 2023, doi: 10.1109/LSENS.2023.3297795.

[2] S. El-Ahmar et al., “The Comparison of InSb-Based Thin Films and Graphene on SiC for Magnetic Diagnostics under Extreme Conditions,” Sensors, vol. 22, no. 14, p. 5258, Jul. 2022, doi: 10.3390/s22145258 .

[3] S. El-Ahmar et al., “Graphene on SiC as a promising platform for magnetic field detection under neutron irradiation,” Applied Surface Science, vol. 590, p. 152992, Jul. 2022, doi: 10.1016/j.apsusc.2022.152992.

[4] T. Ciuk et al., “Defect-engineered graphene-on-silicon-carbide platform for magnetic field sensing at greatly elevated temperatures,” Carbon Trends, vol. 13, no. October, p. 100303, Dec. 2023, doi: 10.1016/j.cartre.2023.100303.Speaker: Wiktoria Reddig (Poznan University of Technology) -

12:00

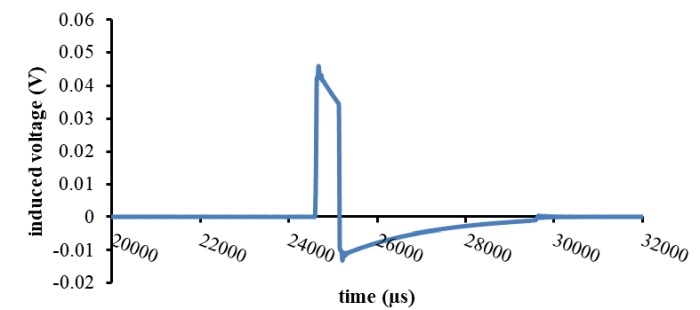

Inductive Microsensor for Biomedical Analysis by Magnetic Nanoparticles Detection 15m

Developing portable sensors is crucial for improving the detection of biological agents. These devices enable rapid, on-site analysis, providing real-time monitoring that is vital for applications such as disease diagnosis and environmental monitoring or the pathogen detection including viruses and bacteria. Portable sensors are compact, lightweight, and easy to use, making them suitable for deployment in various settings, including remote areas and healthcare facilities. By leveraging advanced technologies, these sensors offer high sensitivity and specificity, facilitating timely detection and response to potential threats, thereby enhancing public health and safety. In this context, the use of sensors based on magnetic nanoparticles proves to be particularly relevant [1].

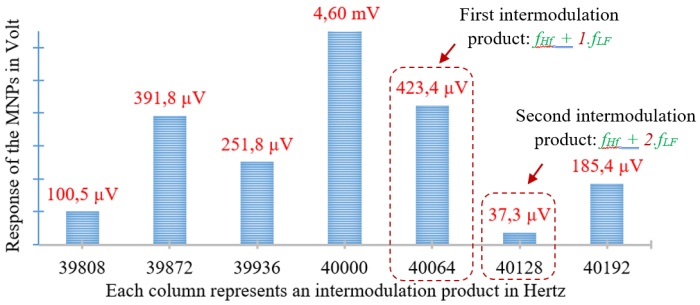

This paper proposes to investigate an innovative inductive microsensor for multipathogen detection based on magnetic nanoparticles (MNPs) fluid integrated into a microfluidic chip platform. The nonlinear detection process employs Faraday’s law, which relates the voltages measured in intermodulation peaks with the magnetic frequency mixing method [2]. This method couples a low frequency ($f_{LF}$) and a high frequency ($f_{HF}$), capitalizing on the nonlinear response of MNPs with diverse sizes and magnetic properties to dual-frequency excitation. Multiphysics simulations including a magnetic shimming analysis have been performed to optimize the parameters of the microsensor, ensuring its optimal performance. Additionally, experimental validation for $f_{LF}$=64 Hz and $f_{HF}$ =40 kHz and MNPs constituted of Fe$_2$O$_3$ S540 with 20 nm of size is conducted to confirm the results obtained from simulations. Figure 1 illustrates the levels of intermodulation peaks acquired, with the first and second peaks serving as reference points utilized to extract the quantity of detected biological agents.

Fig. 1 Experimental results of Fe$_2$O$_3$ S540 20nm MNPs detection.

References

[1] A. Sobczak-Kupiec, et al, “Magnetic nanomaterials and sensors for biological detection, ” Nanomedicine: Nanotechnology, Biology and Medicine, vol. 12, no. 8, pp. 2459-2473, Nov. 2016 doi : 10.1016/j.nano.2016.07.003.

[2] H-J Krause et al,“Magnetic particle detection by frequency mixing for immunoassay applications, ”Journal of Magnetism and Magnetic Materials, vol. 311, no.1, pp. 436-444, April 2017 doi: 10.1016/j.jmmm.2006.10.1164.Speaker: Mr Samy Alati (Sorbonne Université, CNRS, Laboratoire de Génie Electrique et Electronique de Paris, 75252, Paris, France Université Paris-Saclay, CentraleSupélec, CNRS, Laboratoire de Génie Electrique et Electronique de Paris, 91192, Gif-sur-Yvette, France) -

12:15

Magnetoelastic Resonators Functionalized with Metal Organic Frameworks for Wireless Humidity Detection 15m

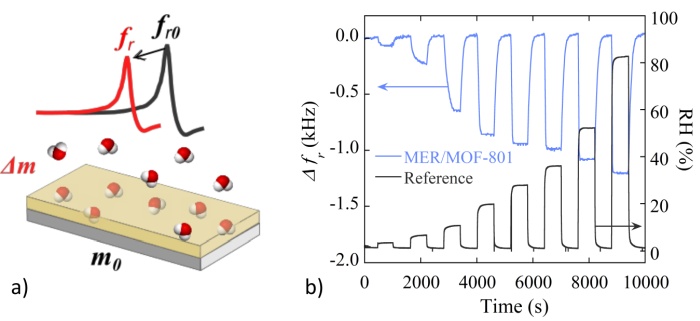

Among other gases, the detection of relative humidity (RH) is crucial in air quality monitoring, food storage or industrial processes control. We present here a wireless humidity sensor based on the magnetoelastic resonance (MER) phenomenon. MER sensors are usually made of magnetostrictive ribbons, which can be driven to mechanical resonance via magnetic field excitation. The basis of their operation is the high sensitivity of their resonance frequency ($f_r$) to different factors, such as the changes in the resonator mass: $\Delta f_r/f_{r0}= -\Delta m/2m_0$ [1]. As their excitation and detection are conducted magnetically, they result especially interesting for remotely detect humidity in closed or inaccessible environments. To provide the MER sensors with water absorption capacity (mass gain $\Delta m$, and thus a detectable change in $f_r$), we propose their functionalization with active layers of water-adsorbent Metal-Organic Framework (MOF) materials (Figure 1a) [2]. MOFs are built by metal ions and organic ligands assembled in 3-dimensional structures, and stand out among the adsorbent materials because of their high porosity, great surface area, tunable pore volume, and tailored selectivity.

Five MOFs with different water-adsorption behavior were synthetized: MOF-801, MOF-808, UiO-66-NH2, Al-Fumarate and CAU-23, and then deposited on the resonator (Fe$_{73}$Cr$_{5}$Si$_{10}$B$_{12}$) surface by spray coating technique. The response of the functionalized sensor (MER resonator + MOF coating) to different levels of humidity was assessed over controlled N$_{2}$/H$_{2}$O flows. The tested MOFs showed promising water harvesting capacity, enabling a successful sensor response to humidity cycles in a wide RH range: 3-85 $\%$ (Figure 1b). MOF water absorption capacity and overall performance of the MER/MOF sensors (sensitivity, stability and selectivity to water molecules) were evaluated. The response time of the devices was about 15 seconds, with stabilization and recovery times in adsorption and desorption processes of less than 1 minute for certain RH ranges. In addition to their solid performance as gas sensors, in our work we found magnetoelastic resonators to be a promising tool for the characterization of the dynamic adsorption capacity of MOF materials (water uptake per g), as they easily provide a quantitative measure of the mass of water adsorbed by the material.

Fig. 1 a) Principle of operation of the MER sensor + MOF layer for humidity detection. b) Response of the sensor with MOF-801 layer to cycles of adsorption and desorption of H$_{2}$O at different humidity levels ($\%$ RH), and comparison with reference sensor (Sensirion SHT45).

References

[1] C. Grimes et al., “Wireless Magnetoelastic Resonance Sensors: A Critical Review,” Sensors, vol. 2, no. 7. MDPI AG, pp. 294–313, Jul. 23, 2002. doi: 10.3390/s20700294.

[2] H. Yuan et al., “Metal-Organic Framework Based Gas Sensors,” Advanced Science, vol. 9, no. 6, p. 2104374, Feb. 2022, doi: 10.1002/ADVS.202104374.Speaker: Beatriz Sisniega (Universidad del País Vasco (UPV/EHU))

-

11:00

-

12:30

→

14:00

LUNCH 1h 30m SOKRATES

SOKRATES

Doktora Kostlivého 576/1 -

14:00

→

15:45

TUE: Session 3 Lecture Hall

Lecture Hall

Košice, Slovakia

Doktora Kostlivého 576/1Convener: Nicoleta Lupu (National Institute of Research and Development for Technical Physics, Iasi, Romania)-

14:00

MR Sensors Integration with Soft Magnetic Elastomers for Tactile Applications 30m

Composite magnetic materials have been explored for several applications ranging from biomedical to robotics [1]. The ability to incorporate homogeneous and dense nanoparticles in elastomer matrix creates opportunities for the integration with magnetic sensors in flexible electronics [2], providing viable for large area applications. In addition, biocompatibility between the elastomers and liquid interfaces have been explored in magnetic cytometry [3] and tactile sensors for harsh environment applications [4].

In this work, we will discuss the integration of magnetoresistive (TMR) sensors in tactile sensors, and demonstrated in surface texture and environment exploration. The use of magnetic elastomer cilia, able to recognize bending upon touch, in x and y directions, using two pairs of magnetic sensors, sensitive in both directions enables to detect $H_{x}$ and $H_{y}$ [5], for a comprehension of the actions over the sensor surface. The magneto-mechanical model for the cilia bending upon touch is presented, so to obtain values for the pressure from the bending angle. A distributed architecture is also presented, where the sensor point location translates the variations in the field mapping distribution over a 2D surface of an elastomer (continuous skin model). Here a point contact action will deform the field matrix, and the 1D or 2D sensors will identify the application point and orientation of the applied force.References

[1] D. Makarov, M. Melzer, D. Karnaushenko, and O. G. Schmidt, “Shapeable magnetoelectronics,” Applied Physics Reviews, vol. 3, no. 1. AIP Publishing, p. 011101, Mar. 2016. doi: 10.1063/1.4938497.

[2] J. Gaspar et al., “Flexible Magnetoresistive Sensors Designed for Conformal Integration,” IEEE Transactions on Magnetics, vol. 53, no. 4. Institute of Electrical and Electronics Engineers (IEEE), pp. 1–4, Apr. 2017. doi: 10.1109/tmag.2016.2623669.

[3] S. Cardoso et al., “Challenges and trends in magnetic sensor integration with microfluidics for biomedical applications,” Journal of Physics D: Applied Physics, vol. 50, no. 21. IOP Publishing, p. 213001, Apr. 27, 2017. doi: 10.1088/1361-6463/aa66ec.

[4] A. Alfadhel and J. Kosel, “Magnetic Nanocomposite Cilia Tactile Sensor,” Advanced Materials, vol. 27, no. 47. Wiley, pp. 7888–7892, Oct. 21, 2015. doi: 10.1002/adma.201504015.

[5] P. Ribeiro, M. Neto, and S. Cardoso, “Strategy for Determining a Magnet Position in a 2-D Space Using 1-D Sensors,” IEEE Transactions on Magnetics, vol. 54, no. 11. Institute of Electrical and Electronics Engineers (IEEE), pp. 1–5, Nov. 2018. doi: 10.1109/tmag.2018.2851928.Speaker: Susana Freitas (INESC-Microsistemas e Nanotecnologias and Instituto Superior Tecnico, ULisboa, Portugal) -

14:30

Lithography Optimization with the Use of Artificial Intelligence for Tunneling Magnetoresistive Sensor Fabrication 15m

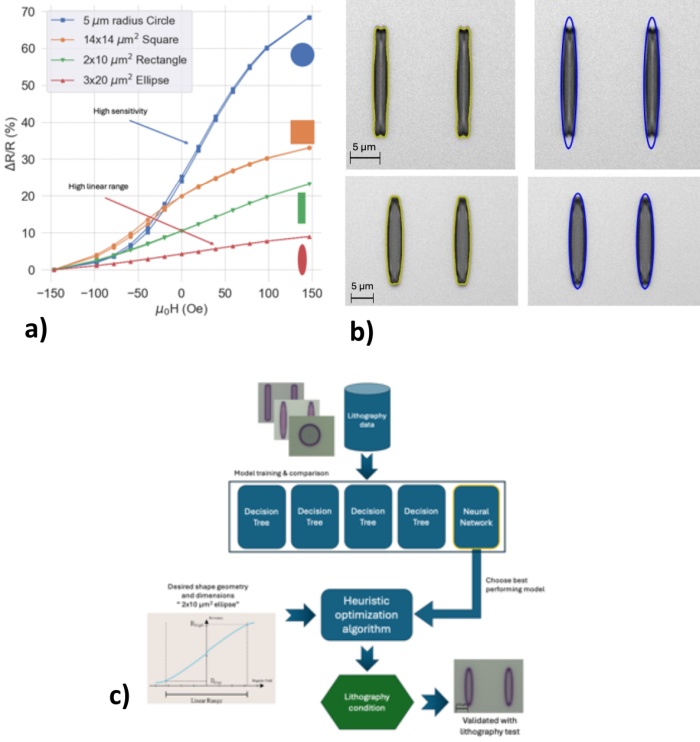

When designing a magnetic tunnel junction (MTJ) sensor, Key Performance Indicators (KPIs) such as sensitivity, linear operating field range and electrical resistance are set by the application specifications. One of the critical design parameters to tune is the geometry of the MTJ device, as shape, dimension, and aspect ratio directly impact KPIs [1]. By choosing the geometry of the device, it is possible to fit its operation method to the purpose of the sensor (e.g. high linear range vs. high sensitivity applications) (Fig. 1a). For the patterning of MTJ’s in an industrial setting, mask aligner lithography serves as a cost effective technique for increased throughput and resolution up to 1 $\mu$m. However due to the nature of shadow printing, mask aligner lithography is prone to undesired effects such as dark erosion. This leads to different shape geometry and dimensions having varying optimal lithography conditions (Fig. 1b). Therefore there is a need of determining the optimal conditions when patterning a new shape and having a tailored response on demand.

In this research several machine learning models were trained with data from 35 lithography tests comprising different shapes and patterned with diverse conditions, to ultimately predict the dimensions and the quality of the patterned shape. The quality was defined as the proportion of area affected by dark erosion to the desired shape. To compare the models’ performance two metrics were used, root mean squared error (RMSE) (for normalized data) and the correlation of determination (R2) for each of the outputs of the models. The best performing models obtained were a Gradient Boosted Tree (GBT) with an average RMSE of 0.19 and an average R$^2$ of 0.86, and a Neural Network (NN) with an RMSE of 0.21 and an R$^2$ of 0.81. While the NN performs worse than the GBT model, the NN was chosen for the inverse analysis due to the nature of GBT, as it finds several conditions leading to the same output, hindering the performance of heuristic optimization algorithms during the inverse search.

Once the best performing model was chosen, inverse analysis was performed with the use of heuristic optimization algorithms such as differential evolution, genetic algorithm, and particle swarm optimization, allowing for the prediction of the optimal lithography conditions to obtain a certain pattern. The structure of the model is shown in Fig. 1c. Obtained predictions were compared with the prediction from the GBT model and if both models were in accordance the conditions were then validated with experimental tests.

Fig. 1 a) Transfer curves from 4 MTJ devices with different shapes and same magnetic stack. b) Top: 2$\times$20 $\mu$m ellipse with significant dark erosion. Bottom: 3$\times$20 ellipse with reduced dark erosion. Exposed with same conditions. c) Model structure.

References

[1] A. V. Silva, D. C. Leitao, J. Valadeiro, J. Amaral, P. P. Freitas, and S. Cardoso, “Linearization strategies for high sensitivity magnetoresistive sensors,” The European Physical Journal Applied Physics, vol. 72, no. 1. EDP Sciences, p. 10601, Oct. 2015. doi: 10.1051/epjap/2015150214.

Speaker: Daniel Sorensen (Instituto Superior Técnico, INESC MN) -

14:45

Modeling Torques in Systems with Spin-Orbit Coupling 15m

Spin-orbit torque (SOT) provides a fast and efficient way to manipulate the magnetization in magnetic devices such as magnetoresistive random access memory (MRAM) [1]. These devices take advantage of the strong spin-orbit coupling (SOC) in the bulk or at the interfaces of heavy metal (HM) layers to generate spin polarized currents. The spin currents are injected into an adjacent ferromagnet (FM), where through spin dephasing the spins align with the magnetization while exerting a torque on the magnetization. In the bulk, the spin currents are generated through the spin Hall effect (SHE) which generates out-of-plane spin currents with in-plane polarization. The HM/FM interface plays a crucial role in the resulting torques as spin-flip scattering can be strong and additional spin currents can be generated through the Rashba-Edelstein effect (REE) at the interface [2]. Typically, the SOTs are modeled by assuming that the spins instantly align with the magnetization in the FM. In this picture, the SOT is determined purely by the spin current on the HM side of the interface, and the interface scattering is captured by the complex spin mixing conductance.

We compare this approach with one that allows for transmission of the transverse spin currents into the bulk by introducing a transmission spin mixing conductance. Furthermore, we explore the addition of the REE through considering spin-flip scattering from a Rashba SOC potential at the interface. In Fig. 1 we show that these two approaches give qualitatively similar results, and with parameter fitting the instant absorption assumption can be a good approximation for bilayers. The addition of the REE yields a stronger field-like torque which does not vanish with decreasing HM thickness in agreement with reported experimental results [3].

Fig. 1 HM thickness dependence of the spin torque in a HM($d_{HM}$)/FM(1.2 nm) bilayer induced by a $10^{12}$A/m$^2$ electrical current. Panel (a) and Panel (b) show the torque generated by the SHE and by both the REE and the SHE, respectively. Dashed lines show the result obtained from considering instant absorption of transverse spin currents.

References

[1] S. Hu et al., “Frontiers in all electrical control of magnetization by spin orbit torque,” Journal of Physics: Condensed Matter, vol. 36, no. 25. IOP Publishing, p. 253001, Mar. 27, 2024. doi: 10.1088/1361-648x/ad3270.

[2] V. P. Amin, P. M. Haney, and M. D. Stiles, “Interfacial spin–orbit torques,” Journal of Applied Physics, vol. 128, no. 15. AIP Publishing, Oct. 21, 2020. doi: 10.1063/5.0024019.

[3] A. Ghosh, K. Garello, C. O. Avci, M. Gabureac, and P. Gambardella, “Interface-Enhanced Spin-Orbit Torques and Current-Induced Magnetization Switching of Pd/Co/AlOx Layers,” Physical Review Applied, vol. 7, no. 1. American Physical Society (APS), Jan. 06, 2017. doi: 10.1103/physrevapplied.7.014004.Speaker: Victor Sverdlov (CDL for NovoMemLog, IuE, TU Wien) -

15:00

Effect of Topography on Extraordinary Magnetoresistive Devices 15m

Magnetoresistive magnetic sensors play a key role in sensing magnetic fields at room temperature, with applications spanning from information storage to biomagnetism. Extraordinary magnetoresistive (EMR) sensors are a promising class of magnetoresistive sensors, which exhibit a magnetoresistance on the order of $7.5\times 10^5\,\%$ at 4T [1]. The extraordinary magnetoresistance is a geometrical effect arising from a field-dependent change in the current paths in devices consisting of two materials with different conductivities. As the effect is very sensitive to the device's geometry, finite element simulations are often used to optimize and predict the performance prior to sensor fabrication. In simulations, however, EMR devices are often assumed flat, unlike real devices, where deposition techniques often result in devices with significant topography.

Here, we consider this topography explicitly by numerically studying metal-semiconductor EMR devices with different 3-dimensional topographies. We vary the geometry of the inner metallic region such as its height and sidewall width because such topographies are usually realistic in sensor production. We show that modeling the 3-dimensional geometry of the EMR sensor is important for capturing the experimental data, as our 3-dimensional numerical model results in good agreement with experimental data [1], exhibiting a low relative error of 4.5 $\%$ for the resistance at 0 T. When using traditional 2-dimensional geometries, this error evaluates to a significantly higher 35.8 $\%$. In addition, we present pathways for both simplifying device fabrication and enhancing the magnetoresistance by making active use of the third dimension.

Acknowledgements

We acknowledge the support of Novo Nordisk Foundation Challenge Programme 2021: Smart nanomaterials for application in life-science, BIOMAG Grant NNF21OC0066526.

References

[1] S. A. Solin, T. Thio, D. R. Hines, and J. J. Heremans, “Enhanced Room-Temperature Geometric Magnetoresistance in Inhomogeneous Narrow-Gap Semiconductors,” Science, vol. 289, no. 5484. American Association for the Advancement of Science (AAAS), pp. 1530–1532, Sep. 2000. doi: 10.1126/science.289.5484.1530.

Speaker: Sreejith Sasi Kumar (Technical University of Denmark) -

15:15

How Physics-Informed Neural Networks (PINNs) could be applied in Magnetic Source Localization and Characterization 15m

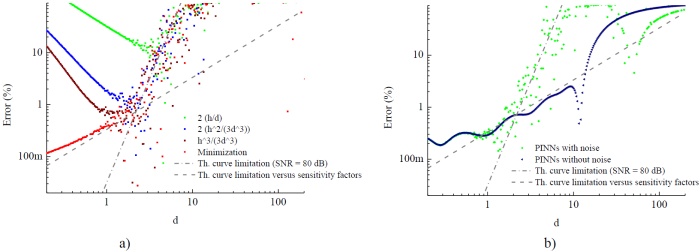

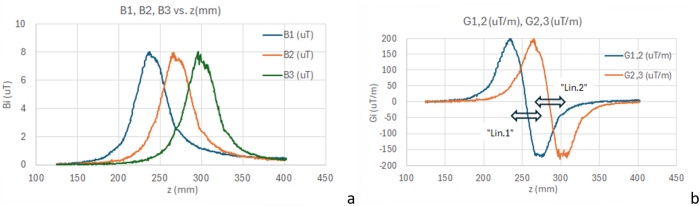

Physics-Informed Neural Networks (PINNs) are a novel class of neural networks that enable the integration of machine learning and physical laws. This relatively recent algorithmic technology, introduced in 2019, has numerous important scientific applications in engineering sciences, such as real-time simulation, digital twins, inverse computation, and finite element methods.

In this work, we have investigated the contribution of PINNs to 1D/2D magnetic source localization and compared their performance to our classical approaches [3]. Numerical simulation/modeling is not always the optimal solution for physics problems, especially when real-time response is required, simulations are computationally expensive, learning data is available, some parameters of the physical model are unknown or inaccessible for modeling, or when Model Order Reduction (MOR) is needed to develop/implement a multi-physics numerical twin.

Based on this observation, we have studied the performance of PINNs on our 1D/2D benchmark setup and evaluated how it can improve results or accelerate computation times, making it more feasible to apply to scenarios with many sensing elements having complex spatial geometric configurations. Figure 1 compares our classical method [3] with a PINN approach. The relevant parameter is the position error of the magnetic dipole location versus the distance to two sensors, $d$, the sensor noise (defined with $SNR_{m}$ cf. [3]), and a discrepancy in sensor sensitivity.

The main results demonstrate the efficiency of PINNs in modeling the physical system based on a reasonable training dataset. Furthermore, once trained, PINNs surpass the classical method based on minimization functions [3] in terms of computation time, making them a promising approach for real-time applications.

Fig. 1 a) Error in the evaluation of the distance, d, of magnetic dipole to the head of detection based on previous modeling [3], b) errors obtain with PINNs. Both $SNR_{m}$ is 80dB. The PINNs $d$ training range (Log scale - 5 million samples) is given from 0.1 to 10 and the magnetization amplitude, $\mu$, varies from (0.3, 1, 3).

References

[1] M. Raissi, P. Perdikaris, and G. E. Karniadakis, “Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations,” Journal of Computational Physics, vol. 378. Elsevier BV, pp. 686–707, Feb. 2019. doi: 10.1016/j.jcp.2018.10.045.

[2] S. Besnard, F. Jurie, and J. Fadili, “Simpinns: Simulation-Driven Physics-Informed Neural Networks for Enhanced Performance in Nonlinear Inverse Problems,” 2023 13th Workshop on Hyperspectral Imaging and Signal Processing: Evolution in Remote Sensing (WHISPERS). IEEE, Oct. 31, 2023. doi: 10.1109/whispers61460.2023.10430751.

[3] C. Dolabdjian and C. Cordier, “Analysis by Systemic Approach of Magnetic Dipole Source Location Performances by Using an IoT Software Gradiometer Head,” IEEE Sensors Journal, vol. 22, no. 8. Institute of Electrical and Electronics Engineers (IEEE), pp. 7709–7716, Apr. 15, 2022. doi: 10.1109/jsen.2022.3156858.Speaker: Prof. Christophe Dolabdjian (GREYC - Normandie Univ. UNICAEN ENSICAEN CNRS) -

15:30

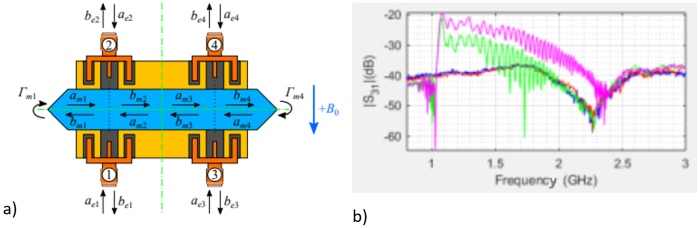

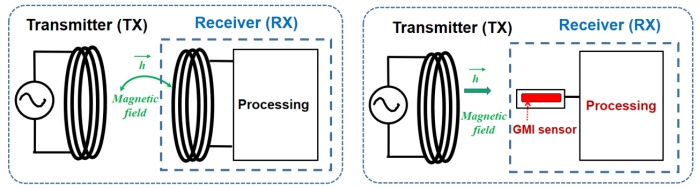

Four-port Characterization of YIG Magnonic Device: a Way to Improve Magnetic Sensors based on YIG Device 15m

For several years, considerable attention has been devoted to advancing high-sensitivity magnetic sensors to enhance measurement capabilities. A recent trend in this pursuit involves leveraging magnonic devices for sensor construction. While only a limited number of studies have produced and characterized such devices, initial performance outcomes appear promising.

These devices harness the spin wave propagation dependency on external magnetic fields. Typically, Yttrium Iron Garnet (YIG) serves as the magnetic material. The implementation of the sensor system involves several elements. A permanent magnetic field must saturate the material. An rc current passing through an exciting antenna generates spin waves by locally causing a precession of the magnetic moment. A receiving antenna is used to capture the propagated spin wave. A representation of the observed external magnetic field is obtained by demodulating the received signal.

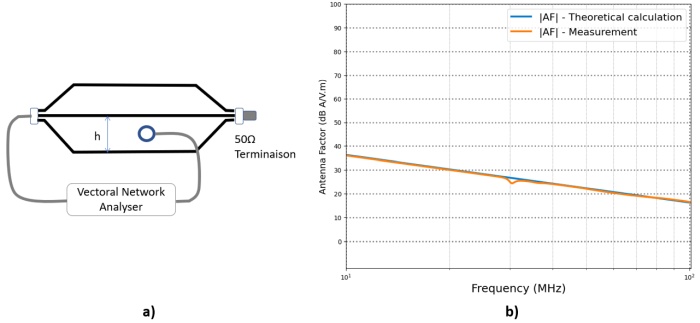

Optimizing this system necessitates the development of a comprehensive model. However, existing physical models primarily focus on spin wave propagation and generation. Our proposed approach adopts a holistic, systemic perspective, treating the sensor element as a four-port coupler (Fig. 1a). This model underscores the intrinsic symmetries of the sensing element and the non-reciprocal nature of spin wave propagation. Notably, our work presents a unified model that accounts for spin wave propagation within microstructured YIG, as well as spin wave reflections along YIG edges, facilitating the assessment of each parameter's impact on the overall system response.

This work presents our latest advancements in the field. Several systems and configurations have been tested, enabling the characterization of various parameters of the couplers. An example of non-reciprocal transmission is provided in Fig. 1b. These results were used to explore new ways to optimize the magnonic sensor.

Fig. 1 a) YIG material and associated antennas, as a four-port network ($a_{e}$ and $b_{e}$ represent incident and reflected power electric wave, $a_m$ and $b_m$ magnetic wave). b) Amplitude of non-reciprocal transmission parameters vs. frequency for a magnetic field $+B_{0}$ (pink), $-B_{0}$ (green), no field (blue), and for antennas alone (red).

Speaker: Sébastien Saez (Normandie Univ, UNICAEN, ENSICAEN, CNRS, GREYC, 14000 Caen, France)

-

14:00

-

15:45

→

16:00

Coffee break 15m MINERVA

MINERVA

Doktora Kostlivého 576/1 -

16:00

→

18:00

POSTER: Session 1 MINERVA

MINERVA

Doktora Kostlivého 576/1Convener: Diana Leitao (Eindhoven University of Technology)-

16:00

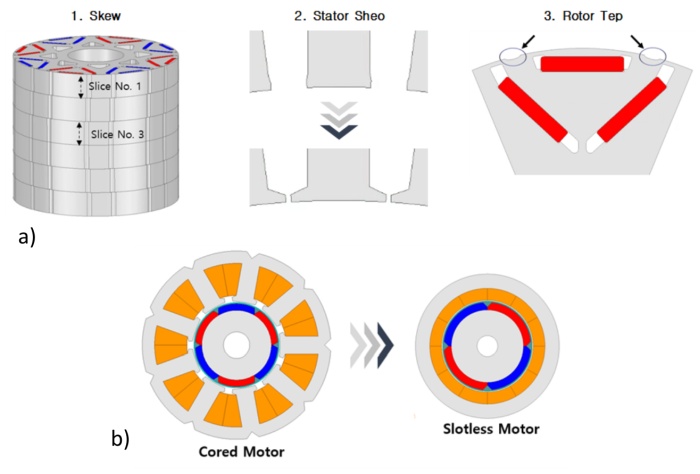

A Study on the Design Method to improve Precision and Efficiency for Servo Motor by Slotless Stator 2h

Servo motors are drivers that accurately control position, speed, acceleration, etc. according to command signals and are mainly used in processes that require precise control, such as semiconductor processes. The precision of servomotors used in precision processes determines the completeness of the final product and accounts for the main power consumption excluding the heating process within the production line. In order to develop servo motors, it is necessary to improve commercialization technology through technology development such as ensuring compatibility, miniaturization/lightweight, and performance improvement. In order to respond to climate change caused by carbon emissions, efforts are being made to legislate emission reduction through international agreements and policies such as the Glasgow Climate Agreement. According to the top 10 carbon emitting countries, carbon emissions generated by global manufacturing powers China, the United States, Japan, Germany, and Korea account for more than 50$\%$ of global emissions. In the case of a slot-type electric motor with a general structure, improvement in precision and efficiency through electromagnetic design has a trade-off relationship, so the development of a slotless type is required to satisfy the two indicators, and the overall performance compared to a slot-type electric motor based on the same output is required. It has been confirmed that it is possible to reduce not only precision but also efficiency. In this paper, a study was conducted on design methods to improve the precision of servomotors, and the output characteristics of slot-type and slotless motors were examined [1].

Fig. 1 a) Example of improving precision by changing the shape of the motor. b) Example of precision improvement using slotless motors.

Acknowledgements

This study was supported by the Ministry of Trade, Industry, and Energy (MOTIE) and Korea Evaluation Institute of Industrial Technology (KEIT) of the Republic of Korea under Grant 20023875.

References

[1] K.-D. Lee, J. Lee, and H.-W. Lee, “Inductance Calculation of Flux Concentrating Permanent Magnet Motor through Nonlinear Magnetic Equivalent Circuit,” IEEE Transactions on Magnetics, vol. 51, no. 11. Institute of Electrical and Electronics Engineers (IEEE), pp. 1–4, Nov. 2015. doi: 10.1109/tmag.2015.2438000.

Speaker: Jae-Kwang Lee (Korea Electronics Technology Institute) -

16:00

A Study on the Method to improve Performance through Variable Stopping Power of Permanent Magnet Hybrid Electronic Brakes 2h

In the case of the permanent magnet electronic brake that will be discussed in this paper, a permanent magnet is placed at the bottom of the stator and a winding is placed in the middle of the stator. In the case of attractive force, it is generated by magnetic energy generated by permanent magnets, and current must be applied to the winding to cancel out the stopping force. In the case of a permanent magnet type electronic brake, the maximum stopping force that can be generated is fixed depending on the permanent magnet inserted at the bottom, and the stopping force cannot be changed even if the load conditions vary. In this paper, we studied a method for outputting a permanent magnet type electronic brake. Two methods were proposed to vary stopping power. The first method is to use an Alico 9 magnet with low coercive force and utilize the magnetization and demagnetization phenomenon according to load conditions to utilize stopping power. The second method is to secure additional stopping power by improving the stator and rotor structures to generate iron loss at the moment stopping power is needed. To verify the validity of this study, a prototype of a permanent magnet brake was manufactured and a dynamo test was conducted.

Fig. 1 a) Permanent magnet electronic brake design process. b) Attractive-force analysis using 3D FEA.

Acknowledgements

This study was supported by the Ministry of Trade, Industry, and Energy (MOTIE) and Korea Evaluation Institute of Industrial Technology (KEIT) of the Republic of Korea under Grant 20023875.

References

[1] K.-D. Lee, J. Lee, and H.-W. Lee, “Inductance Calculation of Flux Concentrating Permanent Magnet Motor through Nonlinear Magnetic Equivalent Circuit,” IEEE Transactions on Magnetics, vol. 51, no. 11. Institute of Electrical and Electronics Engineers (IEEE), pp. 1–4, Nov. 2015. doi: 10.1109/tmag.2015.2438000.

Speaker: Jae-Kwang Lee (Korea Electronics Technology Institute) -

16:00

Domain Wall Imaging in Rapidly Solidified Amorphous Submicronic Wires 2h

Rapidly solidified amorphous submicronic glass-coated wires with diameters between 100 and 950 nm, featuring either high or nearly zero magnetostriction, present a bistable magnetic behavior [1], which relies on the propagation of a single magnetic domain wall at velocities that differ considerably in wires with high magnetostriction as compared to those with nearly zero magnetostriction.

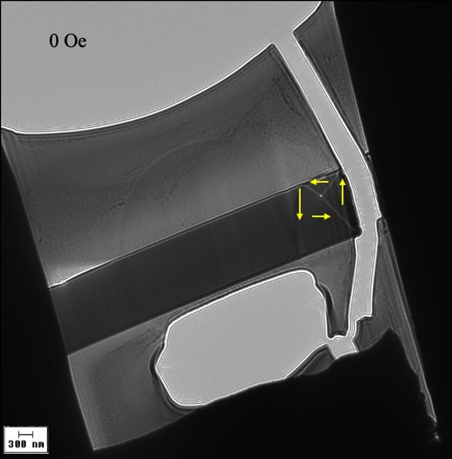

Here, we report on the Lorentz microscopy investigation of magnetic domain walls in rapidly solidified submicronic Fe$_{77.5}$Si$_{7.5}$B$_{15}$ and (Co$_{0.94}$Fe$_{0.06}$)$_{72.5}$Si$_{12.5}$B$_{15}$ amorphous wires with high and nearly zero magnetostriction, respectively. Imaging has been performed using a Libra 200 MC Carl Zeiss ultra-high-resolution microscope in Fresnel configuration. Domain wall structures have been observed under an applied field with various amplitudes and directions. Lorentz microscopy data has been associated with hysteresis loop and domain wall velocity measurements for a comprehensive investigation.

Figure 1 shows a domain wall image observed in a nearly zero magnetostrictive sample having 900 nm in diameter, in the absence of an applied field. The domain wall structure does not change with different values of the applied field. Moreover, tilting a field of 900 Oe at small angles with respect to the direction perpendicular to the lamella, does not alter the vortex structure.

Fig. 1 Lorentz microscopy image of a domain wall in a (Co$_{0.94}$Fe$_{0.06}$)$_{72.5}$Si$_{12.5}$B$_{15}$ submicronic amorphous wire with 900 nm in diameter, with no applied magnetic field.

In case of an Fe$_{77.5}$Si$_{7.5}$B$_{15}$ amorphous submicronic wire with high magnetostriction, having the same diameter (900 nm), the vortex domain wall displays an elongation that increases with the value of the applied field. Tilting the field at small angles has the same effect.

The differences in hysteresis loop parameters and in domain wall velocities displayed by the two types of submicronic amorphous wires can be linked to the differences in their domain wall structures. The results are essential towards fully understanding the magnetic behavior of nearly zero and highly magnetostrictive submicronic amorphous samples.

Acknowledgements

Financial support from the MCID Nucleu Program (PN 23 11 01 01 - contract 18N/2023) is highly acknowledged.

References

[1] S. Corodeanu, C. Hlenschi, C. Rotărescu, H. Chiriac, N. Lupu, and T.-A. Óvári, “Structural relaxation in metastable magnetic submicronic wires,” Journal of Alloys and Compounds, vol. 905, 164260, June 2022. doi: 10.1016/ j.jallcom.2022.164260.

Speaker: Dr Tibor-Adrian Óvári (National Institute of Research and Development for Technical Physics, Iasi, Romania) -

16:00

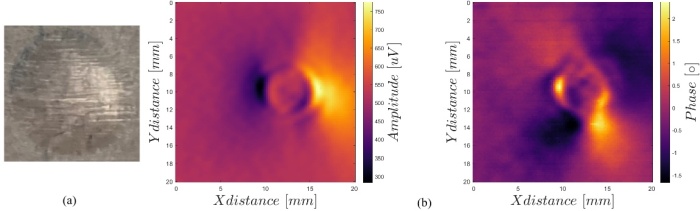

Eddy Current Testing with TMR Probes for Enhanced Quality Control of Arc Stud Welds 2h

In the automotive industry, ensuring the highest quality of welded components is vital for safety and meeting end-user expectations. Current quality control (QC) practices in welding operations primarily rely on mechanical inspection and reactive procedures. To enhance QC efficiency and anticipate quality issues without destructive testing, it is necessary to apply non-destructive testing (NDT) techniques.

This paper explores the application of Eddy Current Testing (ECT), an NDT technique to QC arc stud welding, a process used to join screws/studs to metal plates. This process might create several defects like weld voids, cracks, and porosity [1] which can be detected earlier. ECT, a contactless electromagnetic technique induces and measures electrical currents within conductive materials [2]. Variations in conductivity, often caused by defects, are detected through changes in the induced currents. ECT capability at identifying surface and near-surface defects that escape visual inspection, makes it a valuable tool for comprehensive welding QC.

This work uses a magneto-resistive (MR) differential-based eddy current probe, offering superior spatial resolution, sensitivity, and bandwidth compared to conventional inductive probes [3], [4]. Employing the differential heterodyne technique, the aim is to optimize the magnetic field response's relative variation while minimizing the impact of inductive coupling on the measured signal [5]. The detection employs two identical MR sensors with a 1 mm pitch, each featuring an array of 26 magnetic tunnel junctions (MTJs) in series, with dimensions of 100$\times$100 $\mu m^2$. A scan image of a weld alongside the photograph (Fig. 1) highlights the capability to accurately identify the weld region under specific parameters: 0.5 $_{App}$ stimulation line at 2 kHz and a sensor bias of 300 mVpp at 25 kHz.

Fig. 1 Weld photograph (a) and magnitude and phase scan (b).

This paper focuses on understanding the scans conducted over real automotive welds. Starting with the analysis of identical plates containing machined buried defects at different distances from the scan surface, ranging from 0.1 up to 0.4 mm. The aim is to comprehend the probe's response to these defects, thereby enabling the recognition in actual welds. Throughout this process, COMSOL models were fine-tuned to aid in and validate weld imaging. This research contributes to advancements in NDT by demonstrating the effectiveness of an ECT probe design for welding QC.

Acknowledgements

Project GrenAuto Mobilising Agendas for Business Innovation, funded by the Recovery and Resilience Plan and by European Funds NextGeneration EU.

References

[1] “Welding - Arc stud welding of metallic materials (ISO 14555:2017),” 2017.

[2] J. García-Martín, J. Gómez-Gil, and E. Vázquez-Sánchez, “Non-destructive techniques based on eddy current testing,” Sensors, vol. 11, no. 3. pp. 2525–2565, Mar. 2011. doi: 10.3390/s110302525.

[3] M. Pelkner, R. Pohl, T. Erthner, R. Stegemann, M. Kreutzbruck, and N. Sergeeva-Chollet, "Eddy Current Testing with High-spatial Resolution Probes using MR Arrays as Receiver," presented at the 7th International Symposium on NDT in Aerospace, 16-18 Nov. 2015, Bremen, Germany. [Online]. Available: https://www.ndt.net/?id=18969.

[4] B. Ribes Sáez, N. Sergeeva-Chollet, F. Cardoso, L. Bragado, C. Fermon, S. Cardoso, P. Freitas, M. Piedade, and L. Rosado, "Results of MR based ET probes for buried flaw detection over different metallic materials," presented at the 11th European Conference on Non-Destructive Testing (ECNDT 2014), Prague, Oct 6-11, 2014. [Online]. Available: https://www.ndt.net/?id=16654.

[5] L. S. Rosado, F. A. Cardoso, S. Cardoso, P. M. Ramos, P. P. Freitas, and M. Piedade, “Eddy currents testing probe with magneto-resistive sensors and differential measurement,” Sens Actuators A Phys, vol. 212, pp. 58–67, Jun. 2014, doi: 10.1016/j.sna.2014.03.021.Speaker: Susana Cardoso (INESC MN, Instituto Superior Técnico) -

16:00

Experimental Study of Magnetic Nanoparticles for Magnetic Separation DNA/RNA 2h

Magnetic nanoparticles have been the subject of much research with their unique properties such as size in the nanoscale and the existence of high magnetic moment which bring a wide range of their applications. It is their ability to respond to an external magnetic field that enables their motion control. Their application in biomedicine is interesting, where they show promise as drug carriers, as heat sources in magnetic particle hyperthermia for cancer therapy, in MRI imaging techniques and also in separation techniques using an external magnetic field [1].

At the same time, separation techniques are notoriously time-consuming and technically demanding, which often brings negative impacts in the process of diagnosis and therapy of various viral and bacterial diseases. Also, the specificity of various viral and bacterial diseases limits the possibilities of using conventional separation techniques due to the low concentration of the captured target substances. One of the new approaches in this field is magnetic separation using magnetic nanoparticles [2].

The thesis deals with the application of magnetic nanoparticles as nucleic acid separation reagents in RT-PCR assays. One of the main objectives of the work is to design such nanoparticle systems that, by their specific properties such as shape, magnetic moment magnitude, or the presence of ligand on the nanoparticle surface, would accelerate the separation of nucleic acids and increase the amount of bound genetic material during RT-PCR testing. The potential of magnetic nanoparticles to bind DNA/RNA molecules is investigated on SiO$_2$-coated Fe$_3$O$_4$-type nanoparticles with a specific organic ligand on the surface. Also, the work is devoted to the preparation of star-shaped nanoparticles, or cubic nanoparticles which by their specific shape can bind DNA/RNA molecules more efficiently compared to spherical nanoparticles. Our synthesized nanoparticles have been investigated for their ability to bind nucleic acids. This type of nanoparticles is also characterized in terms of structure, morphology and magnetic properties.

Speaker: Michael Barutiak (Univerzita Pavla Jozefa Šafárika v Košiciach, Prírodovedecká fakulta, Ústav fyzikálnych vied, Katedra fyziky kondenzovaných látok) -

16:00

Fabrication and Characterization of Heusler Alloy Thin Films and Nanowires 2h

Heusler alloys are suitable materials for sensors and actuators [1]. The current challenge in the utilization of shape memory Heusler alloys remains in their downsizing [2]. In this work we present such materials in the form of thin films and nanowires, which were fabricated using electrodeposition. This approach presents a scalable method for fabrication of shape memory materials, which can be used for sensing and actuation in the nanoscale.

Electrodeposition of Ni$_2$FeGa thin films and nanowires, which show a shape memory behavior due to a martensitic transformation capability, was followed by a complete substitution of the Ga atom in their composition by Tl. The Ga substitution resulted in off-stoichiometric Ni-Fe-Tl nanowires with a phase transition at the temperature of $\approx$ 350 K, confirmed by structural and magnetic analysis.

First-order reversal curve analysis of an array of the Ni-Fe-Tl nanowires reveals a change in their magnetization process before and after the phase transition, enabling contactless sensing mechanism of the nanowires’ magnetostructural response [3,4]. Moreover, the phase transition-driven magnetization variations make the nanowires suitable for hyperthermic application. Wide temperature hysteresis of the nanowires’ phase transition offers a possibility to gradually heat the nanowires under an alternating magnetic field. The heating process can be automatically interrupted after the nanowires transform into the high-temperature phase due to a > 70$\%$ change in the hysteresis losses between the magnetically soft austenite and magnetically hard martensitic phase.

Acknowledgements

The authors would like to thank the following projects for the financial support of the presented research: The projects APVV-16-0079 and APVV-20-0205 of the Slovak Research and Development Agency, and projects VEGA 1/0053/19, VEGA 1/0180/23, as well as the project VVGS-2022-2408 of the UPJS.

References

[1] L. Frolova et al., “Smart Shape Memory Actuator Based on Monocrystalline Ni2FeGa Glass-Coated Microwire,” IEEE Trans Magn, vol. 54, no. 11, pp. 1–5, Nov. 2018, doi: 10.1109/TMAG.2018.2848670.

[2] M. Varga et al., “FORC and TFORC analysis of electrodeposited magnetic shape memory nanowires array,” J Alloys Compd, vol. 897, p. 163211, Mar. 2022, doi: 10.1016/j.jallcom.2021.163211.

[3] C. I. Dobrotǎ and A. Stancu, “What does a first-order reversal curve diagram really mean? A study case: Array of ferromagnetic nanowires,” J Appl Phys, vol. 113, no. 4, p. 043928, Jan. 2013, doi: 10.1063/1.4789613.

[4] M. R. Zamani Kouhpanji, A. Ghoreyshi, P. B. Visscher, and B. J. H. Stadler, “Facile decoding of quantitative signatures from magnetic nanowire arrays,” Sci Rep, vol. 10, no. 1, p. 15482, Sep. 2020, doi: 10.1038/s41598-020-72094-4.Speaker: Michal Varga (Faculty of Materials, Metallurgy and Recycling, Technical University of Kosice, Letna 9, 040 01 Kosice, Slovak Republic) -

16:00

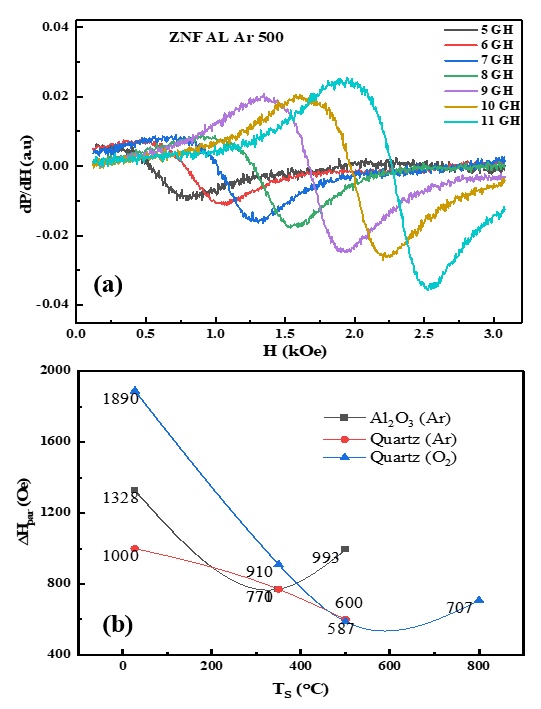

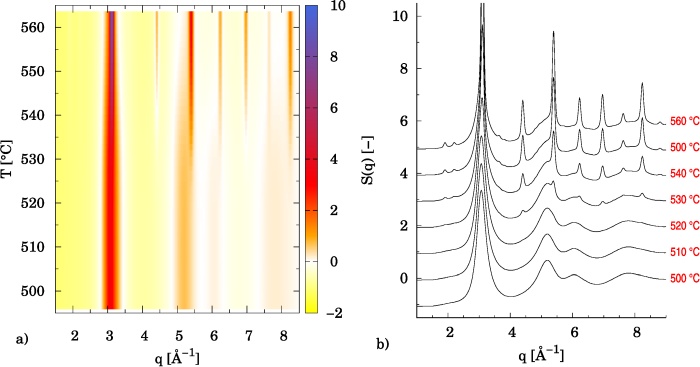

FMR Study of ZnFe2O4 Thin Films in varied Growth Environments 2h

This study investigates the magnetic properties of ZnFe$_2$O$_4$ thin films, emphasizing the impact of growth conditions on their ferromagnetic resonance (FMR) spectra. Utilizing X-ray diffraction (XRD) and Raman spectroscopy, the films were analysed under different substrates, growth temperatures, and gas ambient. Key findings highlight variations in change in FMR line width, saturation magnetization, suggesting a significant influence of growth environments on magnetic behaviour. FMR spectroscopy study has been carried out at room temperature using a broad-band FMR set-up, with an excitation frequency varying from 3 to 18 GHz. For clarity, we have chosen to present data for specific GHz ranges. From the measurements obtained, we calculated the line width ($\Delta H$) and resonance field ($H_r$). It is important to highlight that the FMR signal exhibited greater strength in the argon environment in comparison with the oxygen environment. FMR spectroscopy provides valuable insights into crucial aspects like magnetic anisotropy, magnetic damping, and exchange interactions [1]. These insights are crucial for the development and optimization of spintronic devices [2], providing a deeper understanding of material properties under diverse conditions.

Fig.1 a) FMR spectra of Zinc-ferrite films deposited on Al$_2$O$_3$ substrate at 500 $^\circ$C in an argon environment, and b) The parallel line width ($\Delta H_{par}$) plotted against various $T_S$ (substrate temperature) and substrate types.

References

[1] S. M. Yakout, “Spintronics: Future Technology for New Data Storage and Communication Devices,” Journal of Superconductivity and Novel Magnetism, vol. 33, no. 9. Springer Science and Business Media LLC, pp. 2557–2580, May 31, 2020. doi: 10.1007/s10948-020-05545-8.

[2] Y. Wang, R. Ramaswamy, and H. Yang, “FMR-related phenomena in spintronic devices,” Journal of Physics D: Applied Physics, vol. 51, no. 27. IOP Publishing, p. 273002, Jun. 20, 2018. doi: 10.1088/1361-6463/aac7b5.Speaker: Murtaza Bohra (Mahindra University, India) -

16:00

Glass-coated Ni50Mn37Sb13 Microwires: Synthesis and Magneto-Structural Characterization 2h

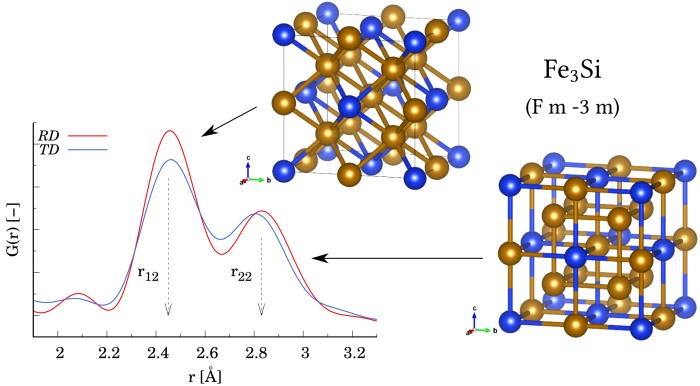

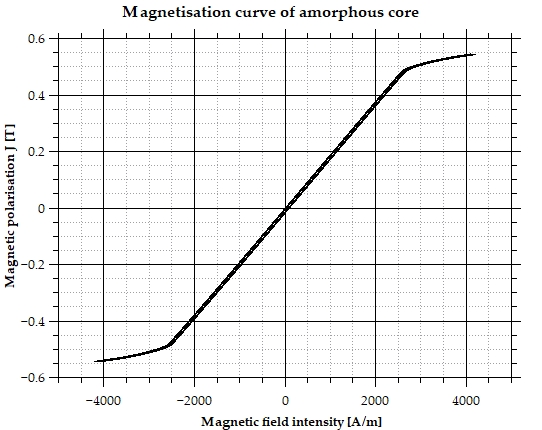

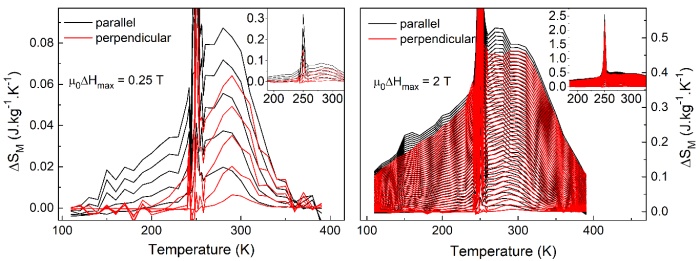

Magnetic Heusler alloys, which undergo a martensitic-like structural transition, display interesting functional properties. Regarding the synthesis of these alloys, most of the work conducted up to now has focused on bulk and ribbon samples prepared using conventional melting and melt-spinning techniques. This work reports the microstructure, structural, magnetic, and magnetocaloric characteristics of polycrystalline glass-coated Ni$_{50}$Mn$_{37}$Sb$_{13}$ microwires obtained by the Taylor-Ulitovsky technique. The results are compared with those obtained for a bulk alloy of the same composition. The microwires exhibited a remarkably uniform diameter, averaging around 200 microns. Elemental chemical composition analyses reveal slight deviations in the Mn and Sb content from the nominal values. At room temperature, austenite shows an L2$_1$-type cubic crystal structure (space group Fm-3m) and undergoes a second-order magnetic phase transition with a Curie temperature ($T_C^A$) of 332 K. The thermomagnetic curve measured under a field of 5 mT in the temperature range from 150 K to 400 K shows the occurrence of a broad first-order martensitic-like phase transition at a temperature of around 233 K. One notable room temperature magnetic characteristic of these samples is their ability to achieve saturation magnetization at a low magnetic field strength of around 0.15 T. For a magnetic field change of 2 T, the produced microwires show a maximum magnetic entropy change $|\Delta SM|_{max}$ of 1.2 Jkg$^{-1}$K$^{-1}$ at the second-order transition of austenite.

Acknowledgements

Work supported by Laboratorio Nacional de Investigaciones en Nanociencias y Nanotecnología (LINAN, IPICyT), CONAHCYT, Mexico (research project CF-2023-I-2143), The Slovak Grant Agency APVV-160079 grant and VEGA 1/0180/23. M. López-Cruz thanks CONAHCYT and SAIA for supporting his Ph.D. studies at IPICyT (scholarship 831827) and his stay at UPJS, Slovakia. The technical support received from Dr. I.G. Becerril Juárez is acknowledged.

Speaker: Michal Varga (Faculty of Materials, Metallurgy and Recycling, Technical University of Kosice, Letna 9, 040 01 Kosice, Slovak Republic) -

16:00

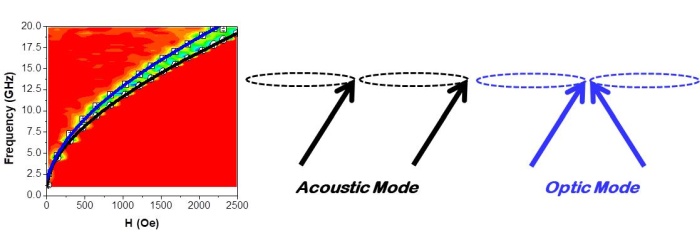

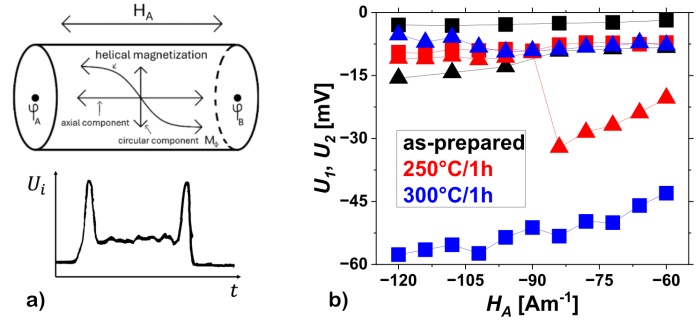

High Frequency of Symmetric/Asymmetric Ferromagnetic Coupled Bilayers 2h

Nowadays, we are immersed in a digital society where information is continually transferred between different devices, forcing us to look for new alternatives that allow the faster transfer of information with the lowest possible energy consumption. Magnetic thin films have been successfully used but their related natural resonance frequency is restricted to the range of a few GHz, and it should be increased to allow for current technological needs [1]. In 2016, Li et al. [2] proved that coupled ferromagnetic bilayers can present higher ferromagnetic resonances, the acoustic and optic modes, as compared to single thin films.

Here, the static and dynamic magnetic responses of symmetric and asymmetric multilayer bimagnetic systems of different non-magnetic spacer thickness have been studied. The symmetric system is composed of Fe(10nm)/Al (0-2nm)/Fe(10nm), and the antisymmetric one of Co(10nm)/Cu(0-8nm)/CoFeB(10nm) [3]. We have observed both the acoustic and optic modes and it is demonstrated that the resonance frequency of the optic mode is very sensitive to the interlayer coupling constant that depends on the geometrical and compositional nature of layers. Particularly, high resonance frequencies can be achieved (over 25 GHz) for Co/CoFeB bilayers with interlayer exchange coupling $J_{eff}$ = (2.7 $\pm$ 0.8) erg/cm$^2$.

Fig. 1 VNA-FMR spectra of Co(10nm)/Cu(3nm)/CoFeB(10nm) trilayer where black and blue lines correspond to the acoustic and optic modes, respectively. Diagrams of both modes.

Acknowledgements

Authors acknowledge financial support from Projects CNS2022-135949 and PID2022-137567NB-C21 by the Spanish Ministry of Science and Innovation, Project FONDECYT/REGULAR 1201102 by ANID, and Projects UIDP/04968/2020 and 2022.03564.PTDC by FCT.

References

[1] K. David and H. Berndt, “6G Vision and Requirements: Is There Any Need for Beyond 5G?,” IEEE Vehicular Technology Magazine, vol. 13, no. 3. Institute of Electrical and Electronics Engineers (IEEE), pp. 72–80, Sep. 2018. doi: 10.1109/mvt.2018.2848498.

[2] S. Li et al., “Tunable Optical Mode Ferromagnetic Resonance in FeCoB/Ru/FeCoB Synthetic Antiferromagnetic Trilayers under Uniaxial Magnetic Anisotropy,” Advanced Functional Materials, vol. 26, no. 21. Wiley, pp. 3738–3744, Apr. 13, 2016. doi: 10.1002/adfm.201600122.

[3] Z. Wei et al., “Static and dynamical behaviour of magnetically coupled Co/Cu/CoFeB trilayers,” Journal of Magnetism and Magnetic Materials, vol. 589. Elsevier BV, p. 171584, Jan. 2024. doi: 10.1016/j.jmmm.2023.171584.Speaker: Rafael Perez del Real (Institute of Materials Science of Madrid, ICMM-CSIC) -

16:00

Inductance Calculation of Small Spoke Motor using Equivalent Circuit 2h

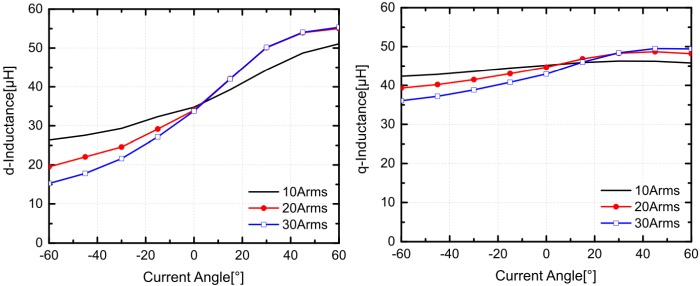

The inductance of an IPM motor is an important factor in determining the performance of the motor.In particular, spoke type motors use salient pole ratios to utilize reluctance torque, so accurate inductance calculation is an important technique. Many papers have previously been published on inductance calculation methods [1-2]. Recently, with the development of computers, the method of calculating inductance using FEM is widely used. However, the process has the disadvantage of being complicated and time-consuming. Of course, when using FEM, the iron core saturation phenomenon can be calculated with high precision, so the inductance calculation result has the advantage of being highly accurate.

Figure 1 shows the inductance calculated by FEM. $L_{d}$ and $L_{q}$ represent the inductance of each $d$-axis and $q$-axis. Inductance varies depending on the magnitude and phase angle of the current. When calculating with an equivalent circuit, a complicated process is required to accurately calculate the magnetic saturation phenomenon.

In this paper, the inductance was calculated using the magnetic equivalent circuit method and the results were compared with the FEM calculation method. A method of increasing accuracy was applied by applying the iron core saturation nonlinear function and the permanent magnet demagnetization function. A comparison of the analysis results will be presented in the full paper.

Fig. 1 Inductance calculation results according to current and phase angle using FEM analysis.

Acknowledgements

This work was supported by the Technology Innovation Program (No. 20023928) funded By the Ministry of Trade, Industry & Energy (MOTIE, Korea).

References

[1] Ki-Doek Lee, Ju Lee, and Hyung-Woo Lee, “ Inductance Calculation of Flux Concentrating Permanent Magnet Motor through Nonlinear Magnetic Equivalent Circuit,” IEEE Transactions on Magnetics, vol. 51, no. 11, Institute of Electrical and Electronics Engineers (IEEE), Article Sequence Number: 8204304, November 2015. doi: 10.1109/TMAG.2015.2438000.

[2] Baichuan Xu, Kai Yang, Senior Member, IEEE, Feng Jiang, Songjun Sun, and Yixiao Luo, “ D-Q Axis Inductance Analytical Calculation for Fractional-Slot Distributed Winding IPM Motor Based on Big-Small Pole Space Method,” IEEE Transactions on Industrial Electronics, vol. 71, no. 2 Institute of Electrical and Electronics Engineers (IEEE), pp.1341-1354, February 2024. doi: 10.1109/TIE.2023.3247779.Speaker: Jeong Jong Lee (Korea Electronics Technology Institute) -

16:00

Influence of Chemical Composition Change on Ni2NbSn – Heusler Ferromagnetic Superconductor 2h

Heusler alloys are a unique class of materials which enable the option to change their physical properties by simple adjustment of the alloy's chemical composition. It was shown in different studies, that changes in chemical composition can lead to tuning of the observed phenomenon, and its enhancement. Well-known Heusler ferromagnetic superconductor Ni$_2$NbSn has a critical temperature of 3 K and Curie temperature of around 13 K. Mainly the value of critical temperature makes the material difficult to study and does not support its practical application.

In the presented work, the influence of chemical doping of Ni$_2$NbSn using Ga, Ge, and Sb elements was investigated. The most crucial parameters were evaluated, such as superconducting transition temperature, and also Curie temperature. The chemical tuning of the mother alloy was performed with 1$\%$ and 2$\%$ doping. It was found that doping may in some cases suppress the superconducting or ferromagnetic properties in the material, but on the other hand, favourable enhancement of superconducting temperature has been observed for 1$\%$ Sb doping, up to 6.42 K. The resistance measurements revealed the background of the coexistence of ferromagnetism and superconductivity can be different than in the case of other chemical doping.

Acknowledgements

This work was supported by the projects APVV-16-0079, Slovak VEGA grant. No. 1/0180/23, 1/0404/21, 2/0058/20. University Science Park TECHNICOM for Innovation Applications Supported by Knowledge Technology– II- Phase, ITMS: 313011D232., supported by the Research \& Development Operational Programme funded by the ERDF.

References

[1] S. Nalevanko, J. Kačmarčík, L. Galdun, et. al., “Ni$_2$NbSn Heusler ferromagnetic superconductor: Magneto-structural and transport characterisation,” Intermetallics, vol. 167, no. 108231, Feb. 2024. doi: 10.1016/j.intermet.2024.108231.

[2] A. Reigle, K. Mason, J. Slattery, et. al., “Superconducting properties of in doped ZrNi$_2$Ga$_{1−x}$In$_x$, ” Solid State Commun, vol. 291, pp. 28–31, Jan 2019. doi: 10.1016/j.ssc.2019.01.015.

Speaker: Samuel Nalevanko (CPM-TIP, UPJS) -

16:00

Influence of Chemical Doping on Magnetic Characteristic of ErMn$_{1-x}$Fe$_{x}$O$_3$ Multiferroic System 2h

ErMnO$_3$ is the improper multiferroic compound with ferroelectric ordering temperature of $T_c$ = 835 K, but with the magnetism presented only below Neel temperature of $T_N$ = 81 K [1]. This temperature is too low for the application purposes. On the other hand, ErFeO$_3$ system does not exhibit the ferroelectric ordering, but it orders magnetically into antiferromagnetic structure below $T_N$ = 643 K [2]. In order to have a multiferroic material with high application potential, one has to ensure that both, ferroelectric and magnetic orderings occur at temperature higher than room temperature. Extrapolating from parent ErMnO$_3$ and ErFeO$_3$ compound we have expected that such a material can be found in the ErMn$_{1-x}$Fe$_{x}$O$_3$ substitutional system. For these reasons we have prepared the Fe-doped ErMnO$_3$ materials and examined their magnetic properties.

Nanopowders of ErMn$_{1-x}$Fe$_{x}$O$_3$ ($0 \leq x \leq 1$) were prepared by nitrate glycine method. The compounds crystallize in hexagonal structure for $0 \leq x \leq 0.2$ and in orthorhombic structure for $0.5 \leq x \leq 1$. The co-existence of both, hexagonal and orthorhombic phase was observed in the concentration range $0.2 < x < 0.5$. Since the multiferroicity was observed in the hexagonal phase, the magnetism was investigated for $0 \leq x \leq 0.2$ compounds. It was found that all compounds order magnetically at low temperatures, exhibiting hysteresis loops [$M(B)$] at 2 K with very low coercivity field of 0.06 T; 0.04 T and 0.035 T and very low remnant magnetization of 0.18 $\mu_{B}/\mathrm{f.u.}$; 0.1 $\mu_{B}/\mathrm{f.u.}$ and 0.08 $\mu_{B}/\mathrm{f.u.}$ for $x$ = 0; 0.1 and 0.2 composition. The hysteresis loops do not saturate at magnetic field of $\mu_0 H$ = 5 T. No visible anomalies can be observed on $dTM(T)/dT$ curves. Anomalies in $d^2TM(T)/dT^2$ which we associate with magnetic phase transition, are located at 76.9 K, 79.7 K and 82.4 K. All samples are paramagnetic at 150 K as proven from $M(B)$ loops at this temperature and the Curie-Weiss fit of the high temperature $M(T)$ curves indicate that the anomaly in $d^2TM(T)/dT^2$ is connected with paramagnetic to weak ferromagnetic / canted antiferromagnetic phase transition.

Concluding, Neel temperature increases with iron doping, but it does not reach the room temperature within the concentration range of stable hexagonal crystal structure. The magnetic ordering phase transition is of higher order. Additional consequences and effects of the Mn-Fe doping in this system will be discussed within the conference contribution.

Acknowledgements

This research has been supported by VEGA Project No. 2/0011/22.

References

[1] F. Yen et al., “Magnetic phase diagrams of multiferroic hexagonal RMnO3 (R = Er, Yb, Tm, and Ho),” Journal of Materials Research, vol. 22, no. 8. Springer Science and Business Media LLC, pp. 2163–2173, Aug. 2007. doi: 10.1557/jmr.2007.0271.

[2] D. Treves, “Studies on Orthoferrites at the Weizmann Institute of Science,” Journal of Applied Physics, vol. 36, no. 3. AIP Publishing, pp. 1033–1039, Mar. 01, 1965. doi: 10.1063/1.1714088.Speaker: Dr Matúš Mihalik (Institute of Experimental Physics, Slovak Academy of Science) -

16:00

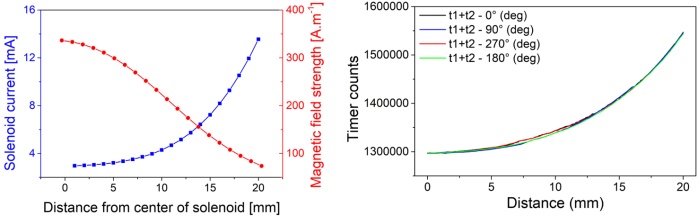

Low-frequency Soft Magnetic Composites produced from BN and Al2O3 Mechanocoated NiFeMo Ferromagnetic Alloy 2h

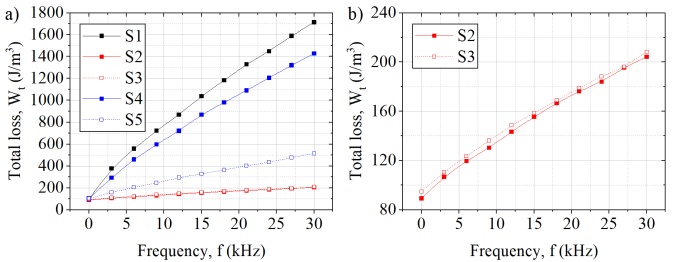

This study examined the effect of the ratio and type of insulation used on the magnetic performance of NiFeMo-based SMCs. We prepared five samples: pure NiFeMo “S1”, two composites with BN-based insulation (1.16 vol$\%$ “S2” and 5 vol$\%$ “S3”), and two Al$_2$O$_3$ (1.16 vol$\%$ “S4” and 5 vol$\%$ “S5”). The ferromagnetic part and the insulator were mixed in 30 ml vials and placed in a custom-prepared setup inside a planetary ball mill at a rotation speed of 500 rpm for 15 minutes. Then, they were compacted in Ar atmosphere at 400 $^\circ$C and 700 MPa for 5 mins and left to cool down.

Fig. 1 Total loss of (a) all samples and (b) samples S2 and S3 measured in the DC-30 kHz frequency range.

Resistivity $\rho_R$ was measured using the contactless method. For S1 $\rho_R$ is 15 $\mathrm{\mu\Omega m}$, S2 190 $\mathrm{\mu\Omega m}$, S3 480 $\mathrm{\mu\Omega m}$, S4 18 $\mathrm{\mu\Omega m}$ and S5 54 $\mathrm{\mu\Omega m}$. Maximum relative permeability $\mu_{max}$ and the real part of complex permeability peak $\mu_r$ reduced with the increased insulation percent, and for sample S1, $\mu_{max}$ and $\mu_r$ have the highest values of around 280 and 120. BN-insulated S2 and S3 have large drops, $\mu_{max}$ are around 190 and 150, and $\mu_r$ 110 and 90, respectively. Al$_2$O$_3$-coated S4 has the lowest drops related to S1, $\mu_{max}$ is 240, and $\mu_r$ is 105; $\mu_{max}$ of sample S5 is around 160, and $\mu_r$ is around 90.

Relaxation frequency $f_r$ tended to grow with the amount of the insulation. In the compact S1, $f_r$ of 6.4 kHz is already high for a pure ferromagnet. BN insulation increased it to around 260 kHz in S2 and 400 kHz in S3. The $f_r$ of Al$_2$O$_3$ in S4 is around 60 kHz and in S5 around 80 kHz. Magnetic loss (Fig. 1), measured in the DC-30 kHz frequency range, confirmed that effect. Hysteresis loss $W_h$ is around 90 J/m$^3$ in all samples. Total energy loss $W_t$ at 30 kHz revealed the superiority of BN-coated powder-based SMCs. The $W_t$ of S1 has a value of around 1700 J/m$^3$; in both S2 and S3, it is around 200 J/m$^3$, and their growth is similar. A low amount of Al$_2$O$_3$ in S4 appears less effective, as its $W_t$ value is around 1430 J/m$^3$; however, 5 vol$\%$ of Al$_2$O$_3$ reduces losses to a greater extent, and $W_t$ is around 510 J/m$^3$.

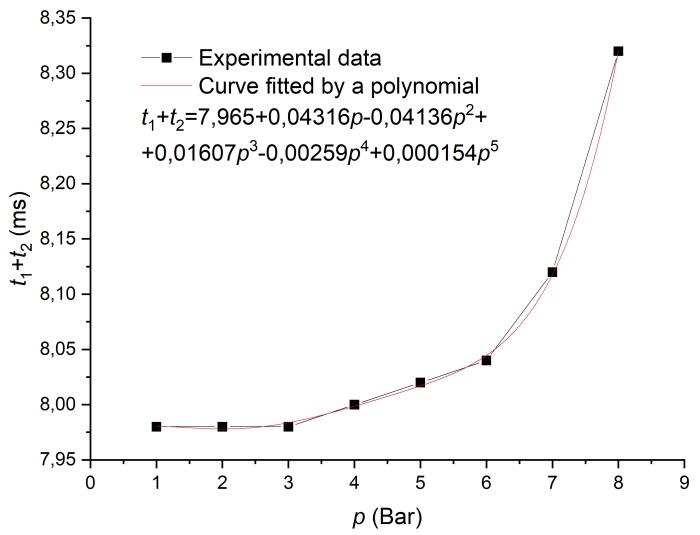

Acknowledgments