Speaker

Description

Ni$_2$FeGa shape memory microwire is a potential material for micro-actuators [1]. One of the methods to demonstrate the actuator property of microwire could be provided by the joule heating method [2]. Interestingly, the micro-diameter (r) of shape memory microwire gives high electric resistance (R) wire following the specific electrical resistivity equation.

$R = \rho \frac{L}{\pi r^{2}}$

The higher electric resistance will ensure sufficient heat to induce a phase transformation in the shape memory microwire. Modulation of the electric current in the form of a triangular signal is beneficial for analyzing the phase transformation behavior in the microwire, which can be confirmed by an in-situ diffraction experiment.

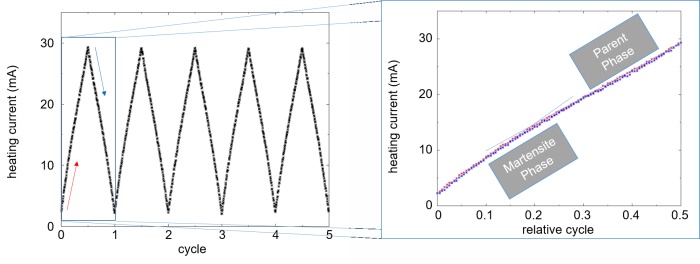

In this work, a sample with stable phase transformation was obtained from glass-removal and heat-treated shape memory microwire. The heating current profile from the sample with 0.1 Hz triangular signal is presented in Fig. 1. The phase transformation between Martensite Phase and Parent Phase is estimated to be around 15 mA. Further measurements show that the microwire can have a million cycles of stable current for phase transformation and an observable phase transformation profile of up to 10 Hz of the triangular signal.

Fig. 1 The heating current profile from the heat-treated shape memory microwire without glass coating with 0.1 Hz triangular signal.

Acknowledgments

This work was supported by Slovak VEGA 2/0086/22 and VEGA 1/0180/23.

References

[1] L. Frolova et al., “Reversible structural transition in monocrystalline Ni2FeGa microwires for shape-memory applications,” Mater. Sci. Eng. B Solid-State Mater. Adv. Technol., vol. 263, p. 114891, 2021, doi: 10.1016/j.mseb.2020.114891.

[2] R. Casati, F. Passaretti, and A. Tuissi, “Effect of electrical heating conditions on functional fatigue of thin NiTi wire for shape memory actuators,” Procedia Eng., vol. 10, pp. 3423–3428, Jan. 2011, doi: 10.1016/J.PROENG.2011.04.564.