Speaker

Description

This study examined the effect of the ratio and type of insulation used on the magnetic performance of NiFeMo-based SMCs. We prepared five samples: pure NiFeMo “S1”, two composites with BN-based insulation (1.16 vol$\%$ “S2” and 5 vol$\%$ “S3”), and two Al$_2$O$_3$ (1.16 vol$\%$ “S4” and 5 vol$\%$ “S5”). The ferromagnetic part and the insulator were mixed in 30 ml vials and placed in a custom-prepared setup inside a planetary ball mill at a rotation speed of 500 rpm for 15 minutes. Then, they were compacted in Ar atmosphere at 400 $^\circ$C and 700 MPa for 5 mins and left to cool down.

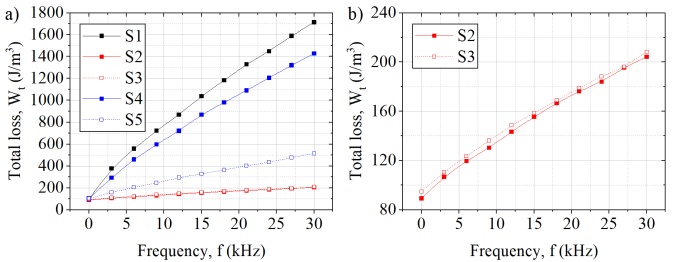

Fig. 1 Total loss of (a) all samples and (b) samples S2 and S3 measured in the DC-30 kHz frequency range.

Resistivity $\rho_R$ was measured using the contactless method. For S1 $\rho_R$ is 15 $\mathrm{\mu\Omega m}$, S2 190 $\mathrm{\mu\Omega m}$, S3 480 $\mathrm{\mu\Omega m}$, S4 18 $\mathrm{\mu\Omega m}$ and S5 54 $\mathrm{\mu\Omega m}$. Maximum relative permeability $\mu_{max}$ and the real part of complex permeability peak $\mu_r$ reduced with the increased insulation percent, and for sample S1, $\mu_{max}$ and $\mu_r$ have the highest values of around 280 and 120. BN-insulated S2 and S3 have large drops, $\mu_{max}$ are around 190 and 150, and $\mu_r$ 110 and 90, respectively. Al$_2$O$_3$-coated S4 has the lowest drops related to S1, $\mu_{max}$ is 240, and $\mu_r$ is 105; $\mu_{max}$ of sample S5 is around 160, and $\mu_r$ is around 90.

Relaxation frequency $f_r$ tended to grow with the amount of the insulation. In the compact S1, $f_r$ of 6.4 kHz is already high for a pure ferromagnet. BN insulation increased it to around 260 kHz in S2 and 400 kHz in S3. The $f_r$ of Al$_2$O$_3$ in S4 is around 60 kHz and in S5 around 80 kHz. Magnetic loss (Fig. 1), measured in the DC-30 kHz frequency range, confirmed that effect. Hysteresis loss $W_h$ is around 90 J/m$^3$ in all samples. Total energy loss $W_t$ at 30 kHz revealed the superiority of BN-coated powder-based SMCs. The $W_t$ of S1 has a value of around 1700 J/m$^3$; in both S2 and S3, it is around 200 J/m$^3$, and their growth is similar. A low amount of Al$_2$O$_3$ in S4 appears less effective, as its $W_t$ value is around 1430 J/m$^3$; however, 5 vol$\%$ of Al$_2$O$_3$ reduces losses to a greater extent, and $W_t$ is around 510 J/m$^3$.

Acknowledgments

This work was realized within the frame of the project “FUCO” financed by the Slovak Research and Development Agency under the contract APVV-20-0072; the Scientific Grant Agency of Ministry of Education of Slovak Republic and Slovak Academy of Sciences (projects VEGA 1/0016/24 and 1/0132/24) and the Internal Scientific Grant of the Faculty of Science, P.J. Šafárik University in Košice (project VVGS-2023-2528).