Speaker

Description

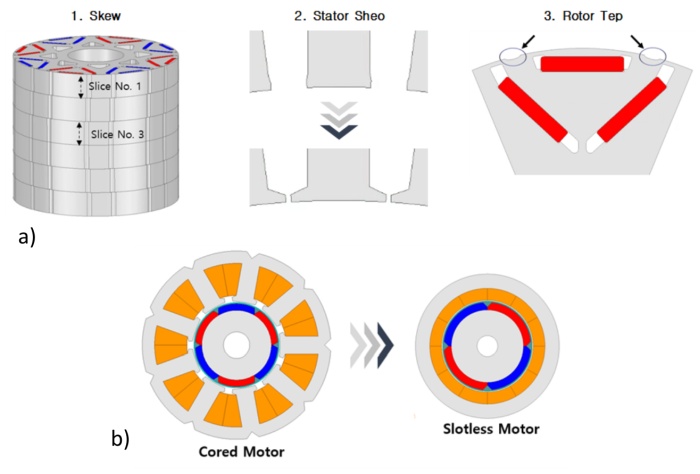

Servo motors are drivers that accurately control position, speed, acceleration, etc. according to command signals and are mainly used in processes that require precise control, such as semiconductor processes. The precision of servomotors used in precision processes determines the completeness of the final product and accounts for the main power consumption excluding the heating process within the production line. In order to develop servo motors, it is necessary to improve commercialization technology through technology development such as ensuring compatibility, miniaturization/lightweight, and performance improvement. In order to respond to climate change caused by carbon emissions, efforts are being made to legislate emission reduction through international agreements and policies such as the Glasgow Climate Agreement. According to the top 10 carbon emitting countries, carbon emissions generated by global manufacturing powers China, the United States, Japan, Germany, and Korea account for more than 50$\%$ of global emissions. In the case of a slot-type electric motor with a general structure, improvement in precision and efficiency through electromagnetic design has a trade-off relationship, so the development of a slotless type is required to satisfy the two indicators, and the overall performance compared to a slot-type electric motor based on the same output is required. It has been confirmed that it is possible to reduce not only precision but also efficiency. In this paper, a study was conducted on design methods to improve the precision of servomotors, and the output characteristics of slot-type and slotless motors were examined [1].

Fig. 1 a) Example of improving precision by changing the shape of the motor. b) Example of precision improvement using slotless motors.

Acknowledgements

This study was supported by the Ministry of Trade, Industry, and Energy (MOTIE) and Korea Evaluation Institute of Industrial Technology (KEIT) of the Republic of Korea under Grant 20023875.

References

[1] K.-D. Lee, J. Lee, and H.-W. Lee, “Inductance Calculation of Flux Concentrating Permanent Magnet Motor through Nonlinear Magnetic Equivalent Circuit,” IEEE Transactions on Magnetics, vol. 51, no. 11. Institute of Electrical and Electronics Engineers (IEEE), pp. 1–4, Nov. 2015. doi: 10.1109/tmag.2015.2438000.