Speaker

Description

Flexible control over magnetic properties in thin films is essential for customization of magnetic devices for data storage, signal processing and especial sensor technology. Oblique incidence deposition (OID) offers the unique capability to prepare ultra-thin films with customized anisotropic surface morphologies and thus adjustable strength and orientation of uniaxial magnetic shape anisotropy simply via deposition at defined oblique orientation relative to the sample plane.

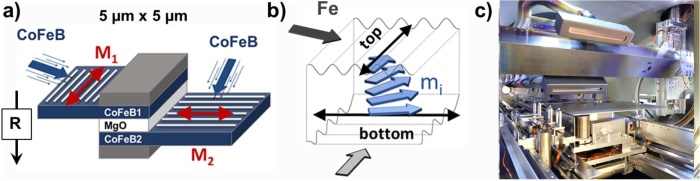

In the recent years we stepwise optimized and extended the OID approach in our group for customization of various magnetic thin film systems. It enabled us to realize single polycrystalline films with high uniaxial magnetic anisotropy, magnetic multilayers with arbitrary crossed magnetization axes for GMR and TMR sensor applications (Fig. 1a, [1-3]) and very recently single films with imprinted vertical spin spiral structures (Fig. 1b). Nuclear forward scattering of synchrotron radiation (NFS) was applied in the different projects to monitor the magnetization depth profile in these films with extra-ordinary spatial resolution which set the basis for further developments of the film structures. This contribution will give an overview on both OID projects (TMR sensors, imprinted vertical spin spirals) and related spin-structures identified via NFS as well as specialized OID coating equipment developed in our group (Fig. 1c).

Fig. 1 a) Schematic drawing of an OID-TMR layer stack. The magnetic response of the sensor to an external magnetic field and thus sensing functionality can be freely set via our OID approach. Uniaxial easy axes (red arrows) can be imprinted into both magnetic electrodes separately with adjustable strength of magnetic anisotropy via the coating process. b) Schematic drawing of a stabilized 90$^\circ$ vertical spin spiral structure in a 10 nm thin iron film. The OID coating parameters define the orientation of the top and bottom easy axes in the film and thus extension of magnetic spiral. c) Photo of our latest, self-made OID coating device for sputter deposition on larger objects.

References

[1] K. Schlage, L. Bocklage, D. Erb, J. Comfort, H. Wille, and R. Röhlsberger, “Spin‐Structured Multilayers: A New Class of Materials for Precision Spintronics,” Advanced Functional Materials, vol. 26, no. 41. Wiley, pp. 7423–7430, Sep. 08, 2016. doi: 10.1002/adfm.201603191.

[2] S. Willing, K. Schlage, R. Röhlsberger et al., “Novel Tunnel Magnetoresistive Sensor Functionalities via Oblique-Incidence Deposition,” ACS Applied Materials & Interfaces, vol. 13, no. 27. American Chemical Society (ACS), pp. 32343–32351, Jul. 02, 2021. doi: 10.1021/acsami.1c03084.

[3] K. Schlage et al., EP 2846334 B1 (2017), EP 3 588 591 A1 (2020), EP 3 587 619 A1 (2021).